corpo

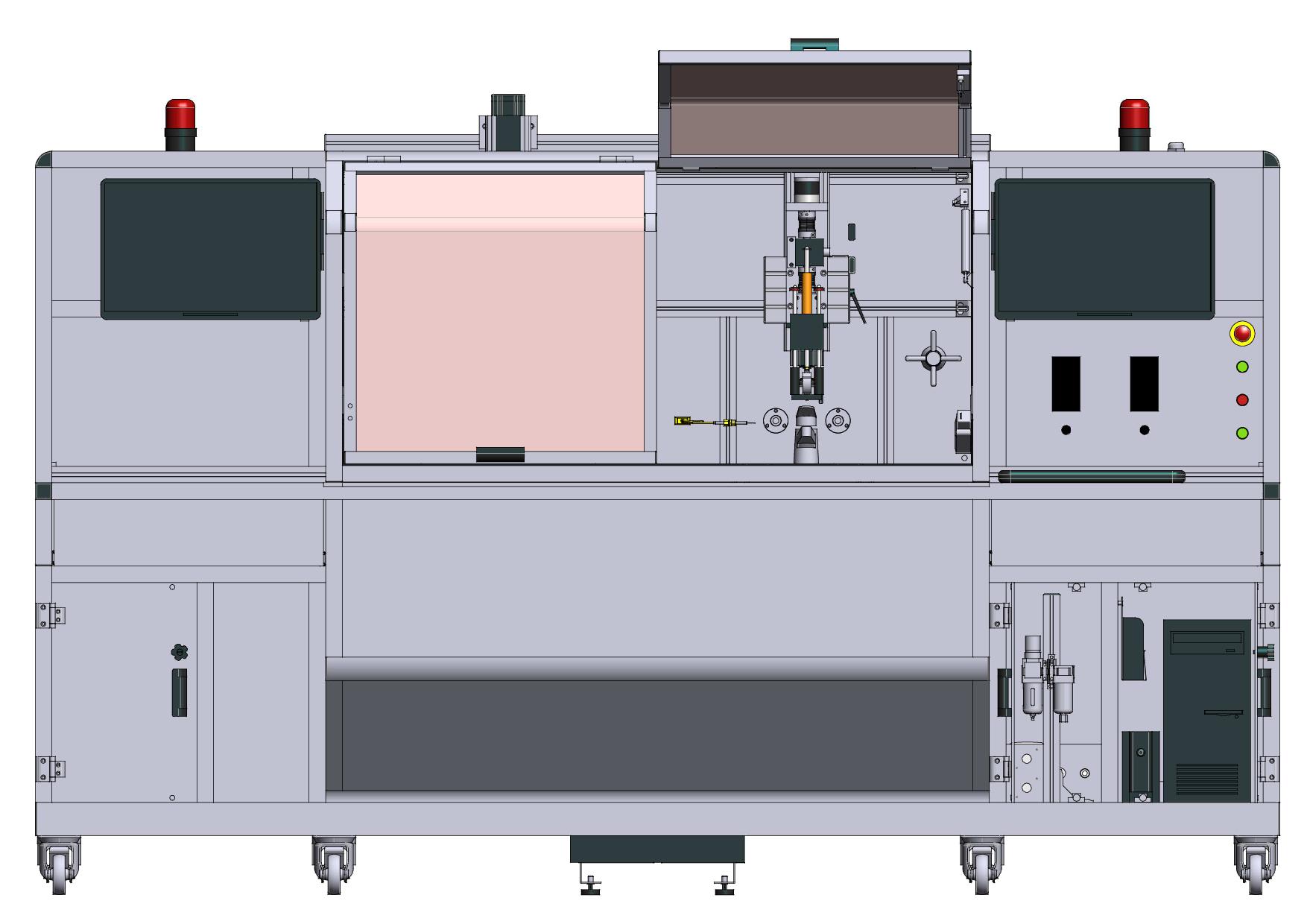

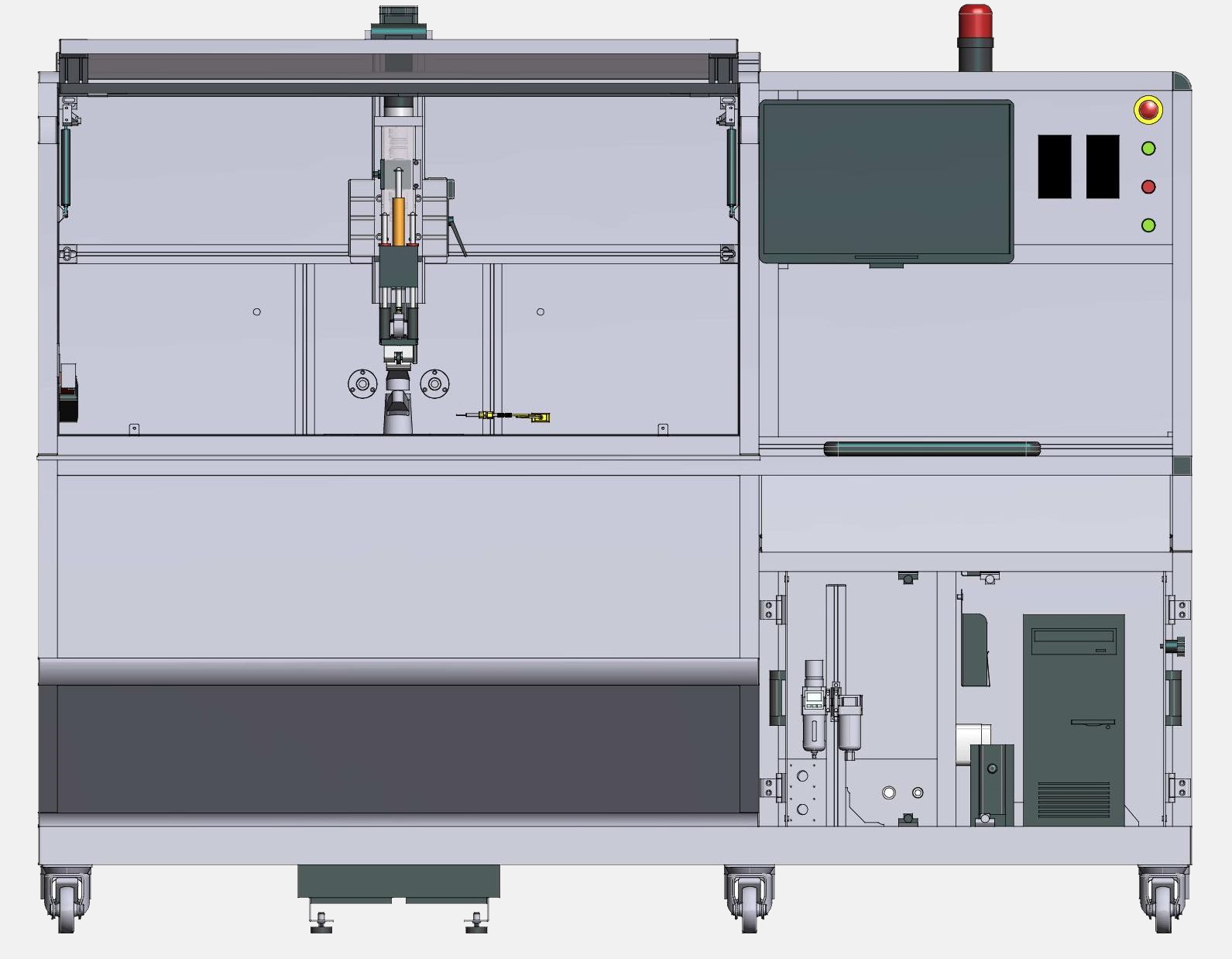

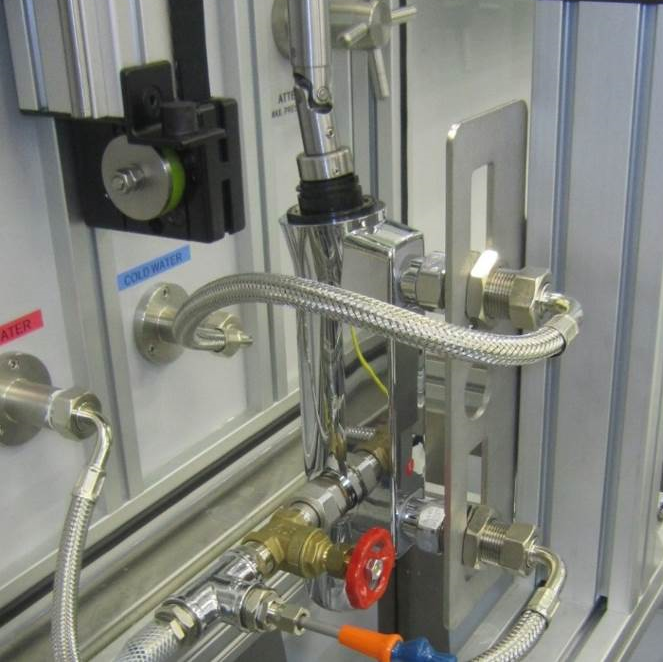

TEST BENCH

ENDURANCE / LIFE TEST

cod. BPR-2L-VM-SWG

(Endurance tests: single lever mixer)

Test benches for endurance tests on single lever mixers, swivel spouts, thermostatic mixers, single taps, diverters and shower mechanism.

Flow-rate: 47+47 L/min

Adjustable flowing pressure: 0,1 - 10 bar

Maximum static pressure: 48 bar

Force: 1 - 44 N

Torque: 1 - 10 Nm

The test benches are equipped with linear motor and rotary motor in order to verify the mechanical resistance and the endurance of many type of component under test.

All the parameters (number of cycles, temperature, pressure, flow-rate, force, torque, angular speed and linear speed) are controlled according the main International standards. All the benches are equipped with a dedicate Aq2tb software for the automatic execution of the tests.

Models available

BPR-1L-VM-SWG: 1 endurance test station

Test bench with one station designed to perfrom endurance tests on single lever mechanical mixers according Standard EN 817, NF 077 and ASME A112.18.1/CSA B125.1

BPR-2L-VM-SWG: 2 endurance test stations

Test bench with two semi-independent test stations (supply pressures and temperatures are in common, all the other working conditions are independent) designed for the execution of endurance tests on single lever mechanical mixers according Standards EN 817, NF 077 and ASME A112.18.1/CSA B125.1

ACCESSORIES AVAILABLE

opz-LM: Equipment for endurance tests of single lever mixer

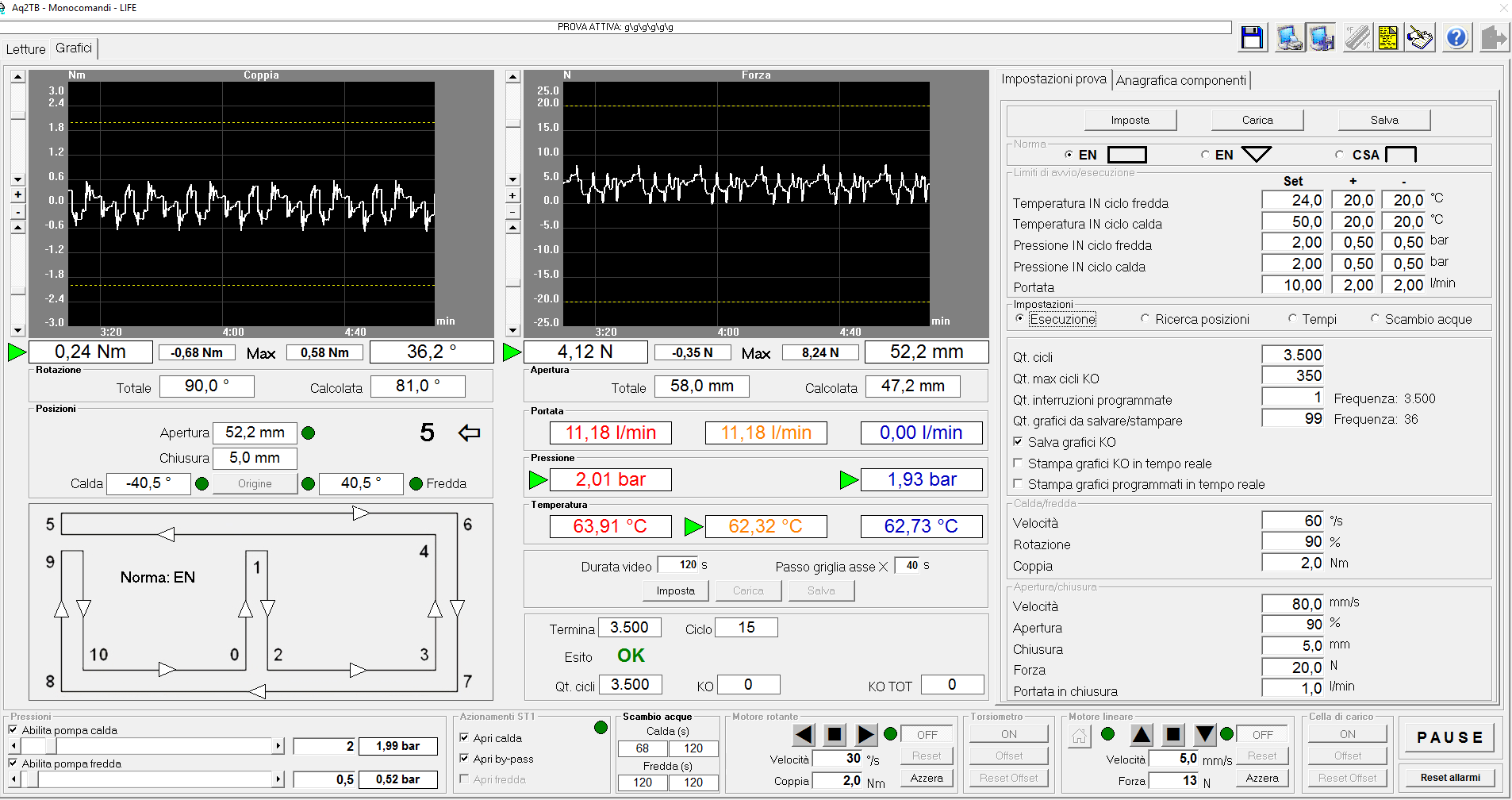

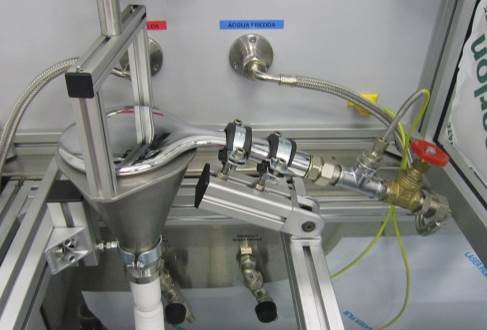

The movement system is used in order to verify the mechanical resistance of the maneuvering device of mechanical mixers.

The procedure consists in subjecting the handle device to a given number of movements at specified pressure and water temperatures. It is possible to perform the test suppling the taps with hot and cold water at the same time (EN standard), alternately with hot and cold water (CSA standard), or with the same water for the entire test.

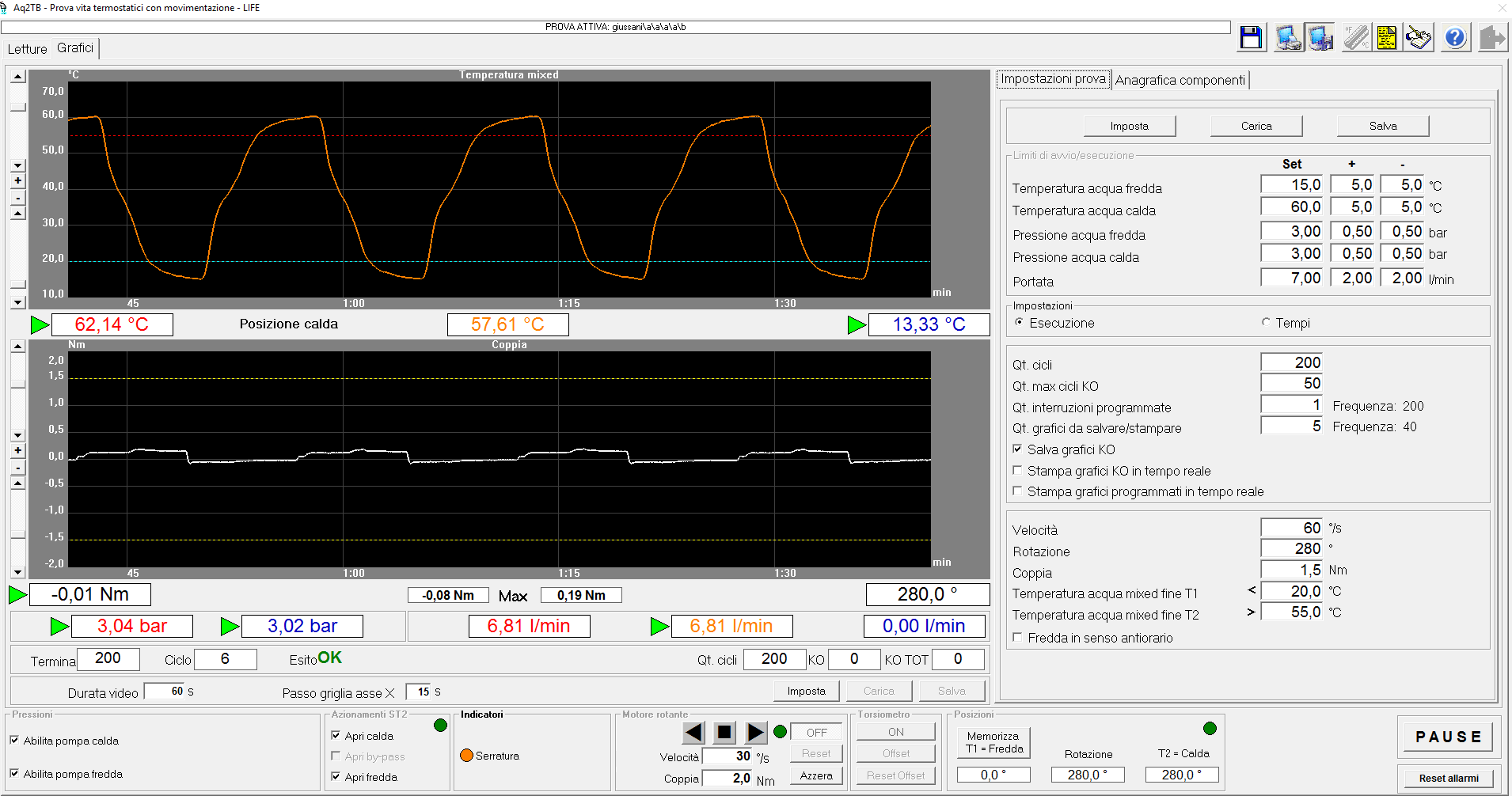

The installed software allows to controls: angle of rotation, angular speed and torque, linear position, linear speed and force.

Standard reference: EN 817 - EN 1286 - ASME A112.18.1/CSA B125.1 - NF077 doc.3

Dedicated software: AQ2TB-LM-ENCSA

Special software available on request: AQ2TB-LM-JOST (joystick cartridges)

Note: the OPZ-LM device is already included in the benaches BPR-1L-VM-SWG and BPR-2L-VM-SWG

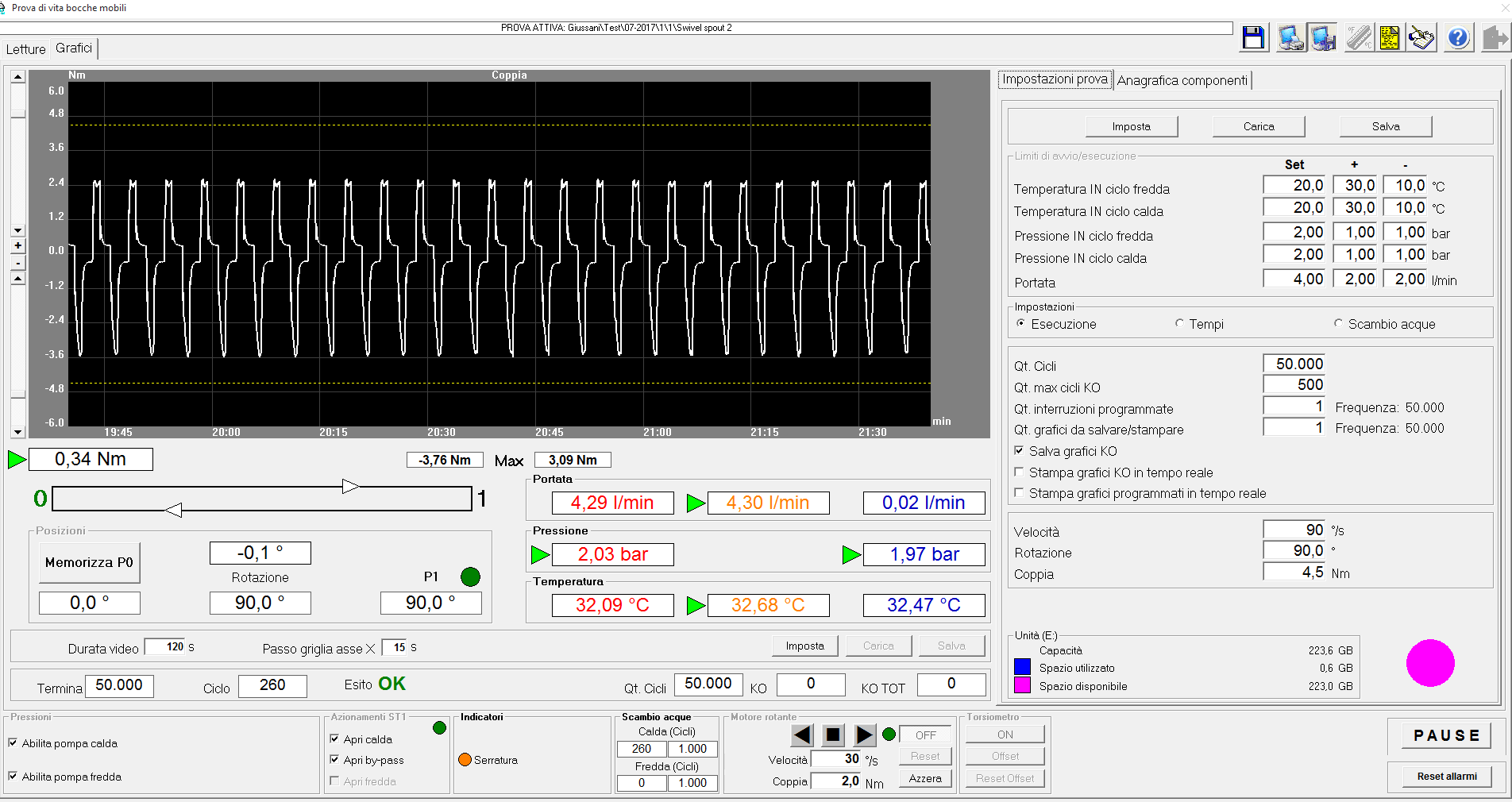

opz-LBM: Equipment for endurance tests of swivel spouts

The movement device is used in order to verify the mechanical resistance of swivel spouts.

It includes the rotary motor used for endurance tests of single lever mixers. A calibrated weight is fixed at the end of the swivel spouts and a hydraulic resistance limits the flow-rate as indicate in the standards. The test cycle consists by subjecting the swivel spouts to a specific number of movements according to the standards, suppling the faucet under test alternately with cold and hot water (CSA standard), only with cold water (EN standard), only with hot water or with hot and cold water at the same time.

The software allows to control: the rotation angle, the angular speed and torque.

Standard reference: EN 817 - EN 1286 - EN 200 - EN 1287 - ASME A112.18.1/CSA B125.1

Dedicated software: AQ2TB-LBM-ENCSA

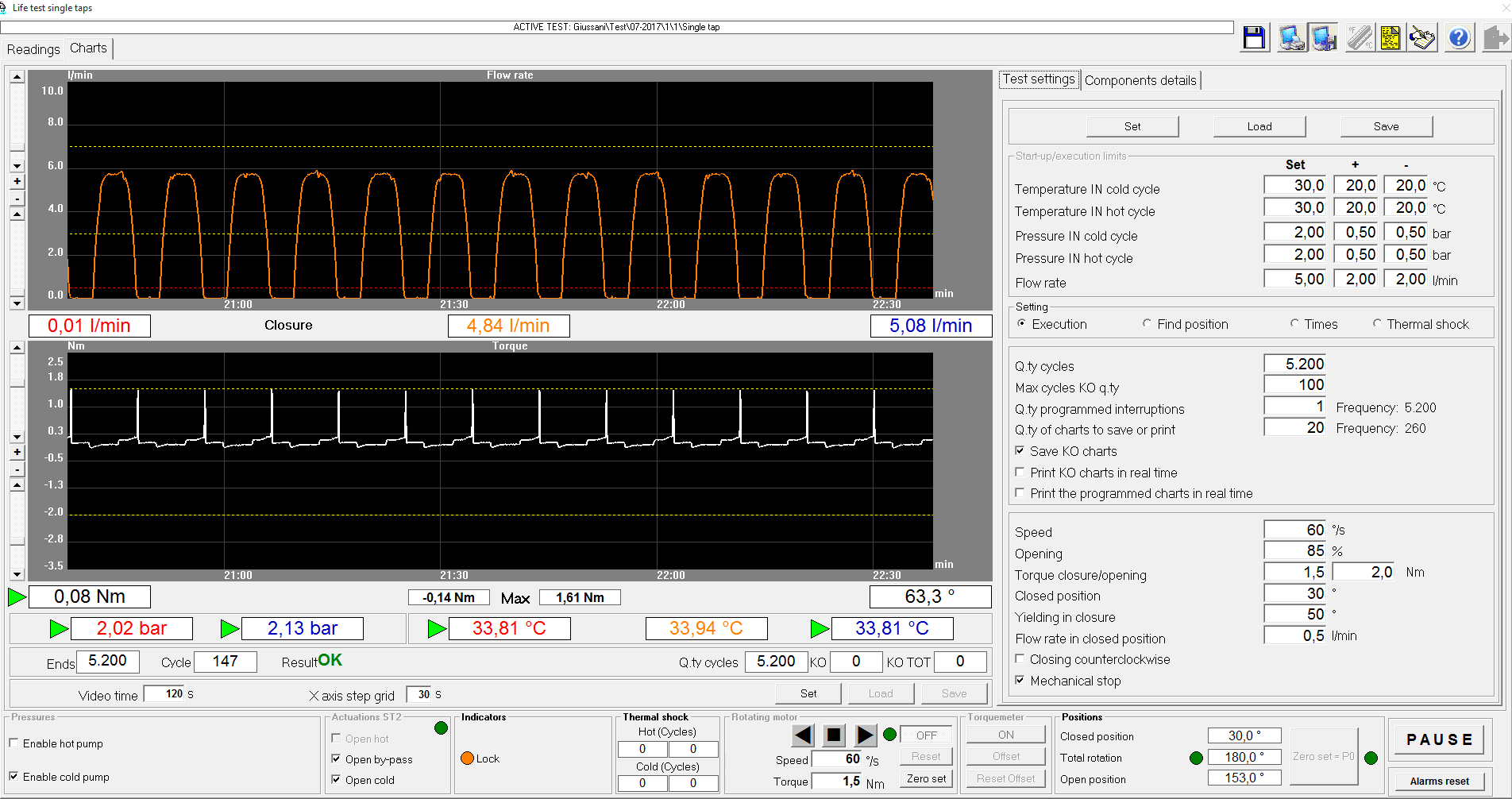

opz-LR: Equipment for endurance tests of traditional and ceramic single taps

The movement device is used in order to verify the mechanical endurance of the on/off flow control devices (traditional and ceramic single taps, valves, thermostatic mixers).

It includes the torque motor used for endurance tests of single lever mixers. A telescopic universal joint connects the flow control under test to the torque motor. A calibrated hydraulic resistance mounted on the tap limits the flow-rate value as indicated in the standards. The test method consists in subjecting the component to a specific number of opening and closing manoeuvre; angular speed and closure torque are defined by the standards. The faucet can be supplied by hot and cold water alternately or with the same water for the entire test.

The software allows to control: the rotation angle, the angular speed and torque

Standard reference: EN 200 - EN 1287 - ASME A112.18.1/CSA B125.1

Dedicated software: AQ2TB-LR-ENCSA

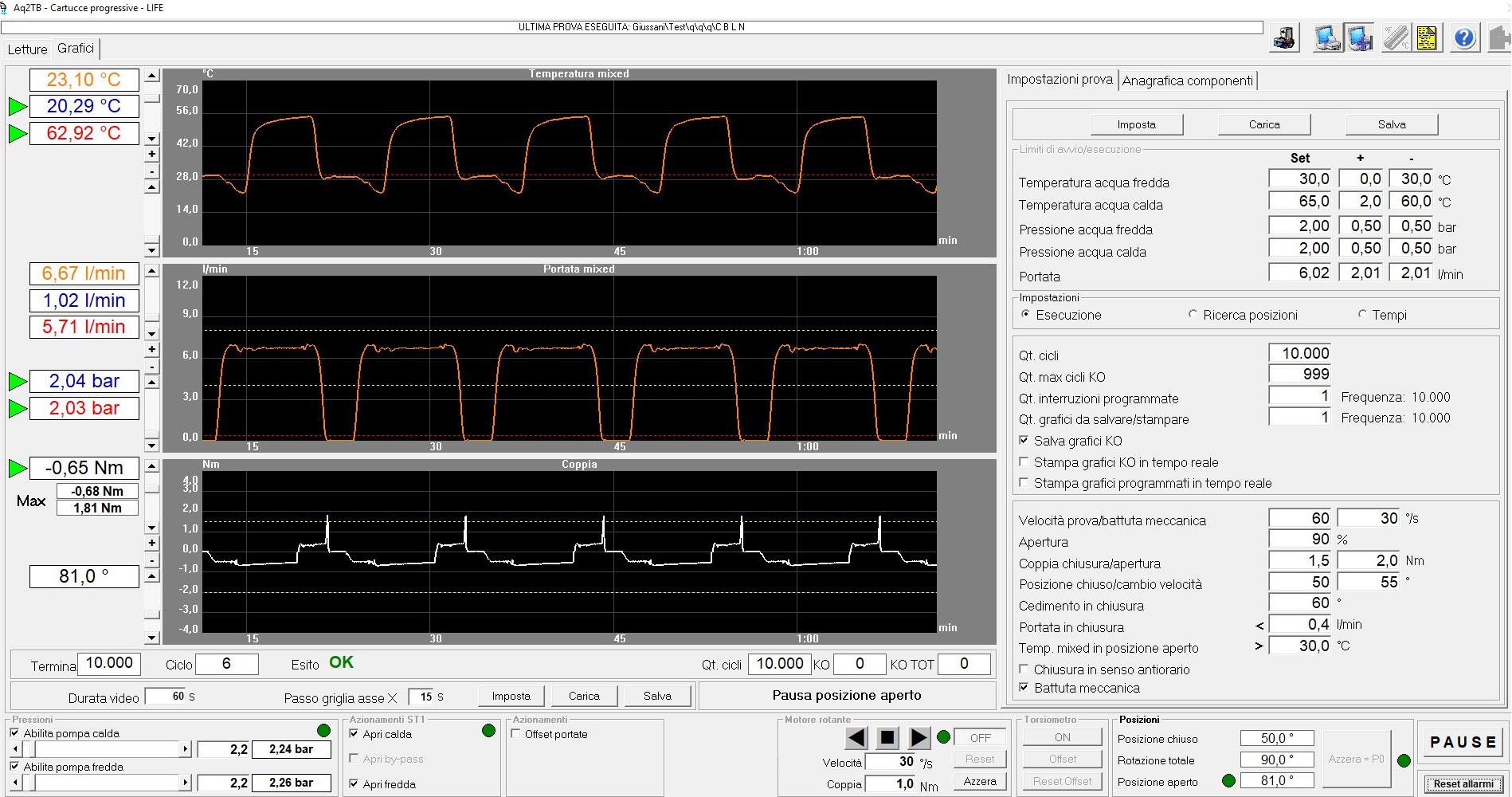

opz-LPC: Endurance tests on progressive cartridges

The movement device is used in order to verify the mechanical endurance of progressive cartridges (from closed position, the cartridge opens at first only cold water, gradually opens also hot water until full hot position).

It includes the torque motor used for endurance tests of single lever mixers. A telescopic universal joint connects the flow control under test to the torque motor. A calibrated hydraulic resistance mounted on the tap limits the flow-rate value as indicated in the standards. The test method consists in subjecting the component to a specific number of opening and closing manoeuvre; angular speed and closure torque are defined by the standards. The faucet is supplied by hot and cold water.

The software allows to control: the rotation angle, the angular speed and torque and the outlet temperature in hot position.

Standard reference: EN 1111 (2017) chap. 16.2

Dedicated software: AQ2TB-LPC-ENCSA

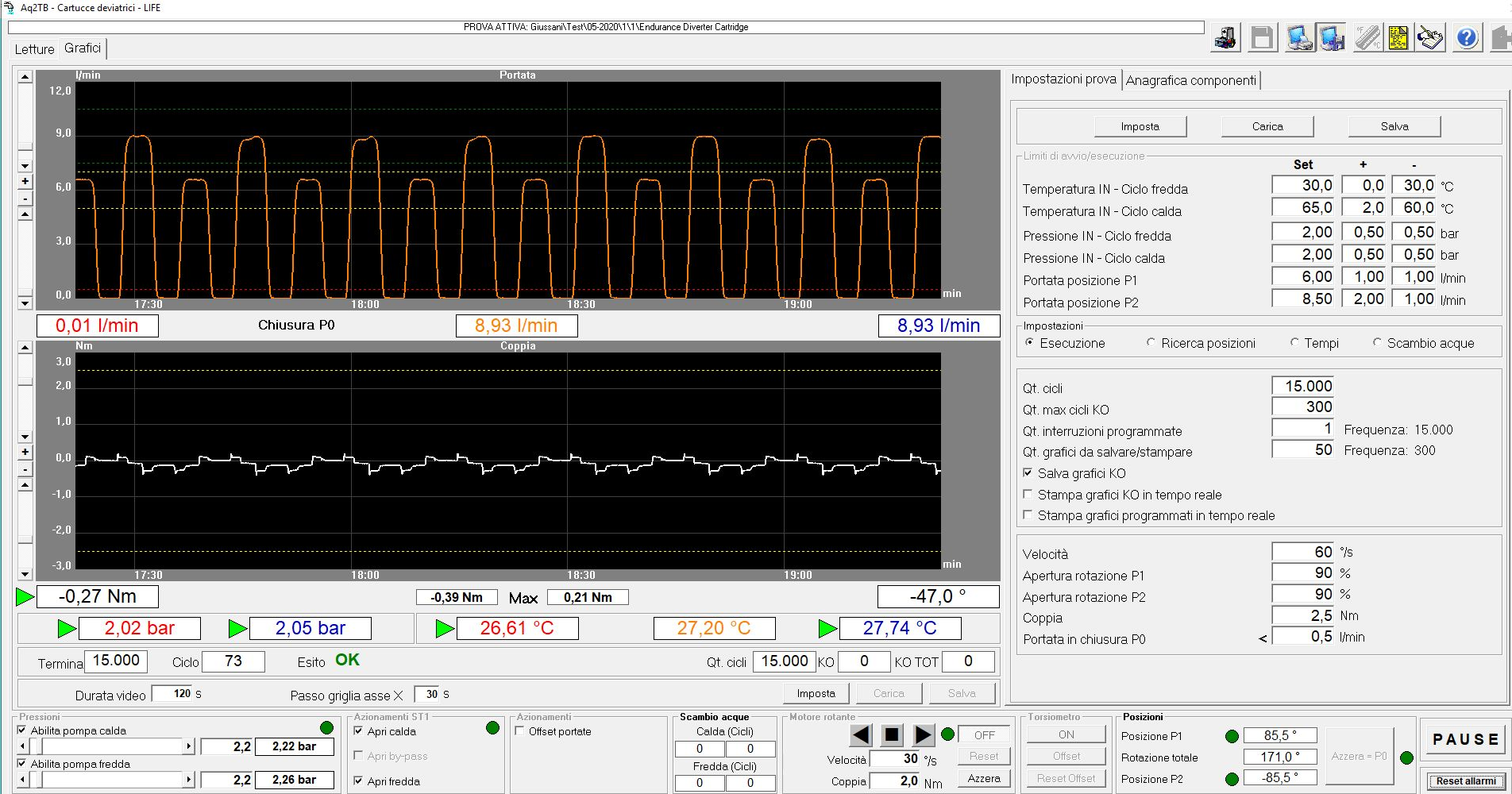

opz-LCD: Endurance tests on diverter cartridges

The movement device is used in order to verify the mechanical endurance of diverter cartridges (cartridges with two separate outlets and one closed position in the centre).

It includes the torque motor used for endurance tests of single lever mixers. A telescopic universal joint connects the flow control under test to the torque motor. A calibrated hydraulic resistance mounted on the tap limits the flow-rate value as indicated in the standards. The test method consists in subjecting the component to a specific number of cycles between the two open positions and the central closed position; angular speed is defined by the standards. The faucet can be supplied by hot and cold water alternately or with the same water for the entire test.

The software allows to control: the rotation angle, the angular speed and torque.

Standard reference: EN 1111 (2017) chap. 16.4

Dedicated software: AQ2TB-LCD-ENCSA

opz-LD: Equipment for endurance tests of automatic diverters

The movement device is used in order to verify the mechanical endurance of any kind of linear diverters, with or without automatic return (example: bath to shower diverters or kitchen diverters).

It includes the linear motor used for endurance tests of single lever mixers. A calibrated hydraulic resistance mounted on the tap limits the flow-rate value as indicated in the standards. The test method consists in subjecting the component to cycles of repeated switch from one outlet to the other (including the pressure drop for the return of automatic diverters). The faucet can be supplied by hot and cold water alternately or with the same water for the entire test.

The software allows to control: the stroke of the device, the linear speed and force.

Standard reference: EN 817 - EN 1286 - EN 200 - EN 1287 - ASME A112.18.1/CSA B125.1

Dedicated software: AQ2TB-LD-ENCSA

opz-LCT: Equipment for endurance tests of thermostatic mixers

The movement device is used in order to verify the mechanical endurance of temperature control of thermostatic mixers.

It includes the torque motor used for endurance tests of single lever mixers. A telescopic universal joint connects the temperature control under test to the torque motor. The test method consists in subjecting the component to a specific number of rotations from cold to hot position and return.

The software allows to control: the rotation angle, the angular speed, torque and the correct outlet temperature in cold and hot position.

Standard reference: EN 1111 - NF 077 doc.4

Dedicated software: AQ2TB-1LM-DRIVE

opz-LMWS: Equipment for endurance tests of shower mechanism and multi-ways selectors

The movement device is used in order to verify the mechanical resistance of multi-ways selectors (rotating diverters, shower mechanisms, ect…).

It includes the torque motor used for endurance tests of single lever mixers. A regulation valve limits the flow-rate as indicate in the standards. The test cycle consists by subjecting the selector to a specific number of movements according to the standards. The device assures an alternated movement suppling the faucet under test alternately with cold and hot water (CSA standard) or with the same water for the entire test

The software allows to control: the rotation angle, the angular speed, and torque.

Standard reference: ASME A112.18.1/CSA B125.1

Dedicates software: AQ2TB-LMWSENCSA

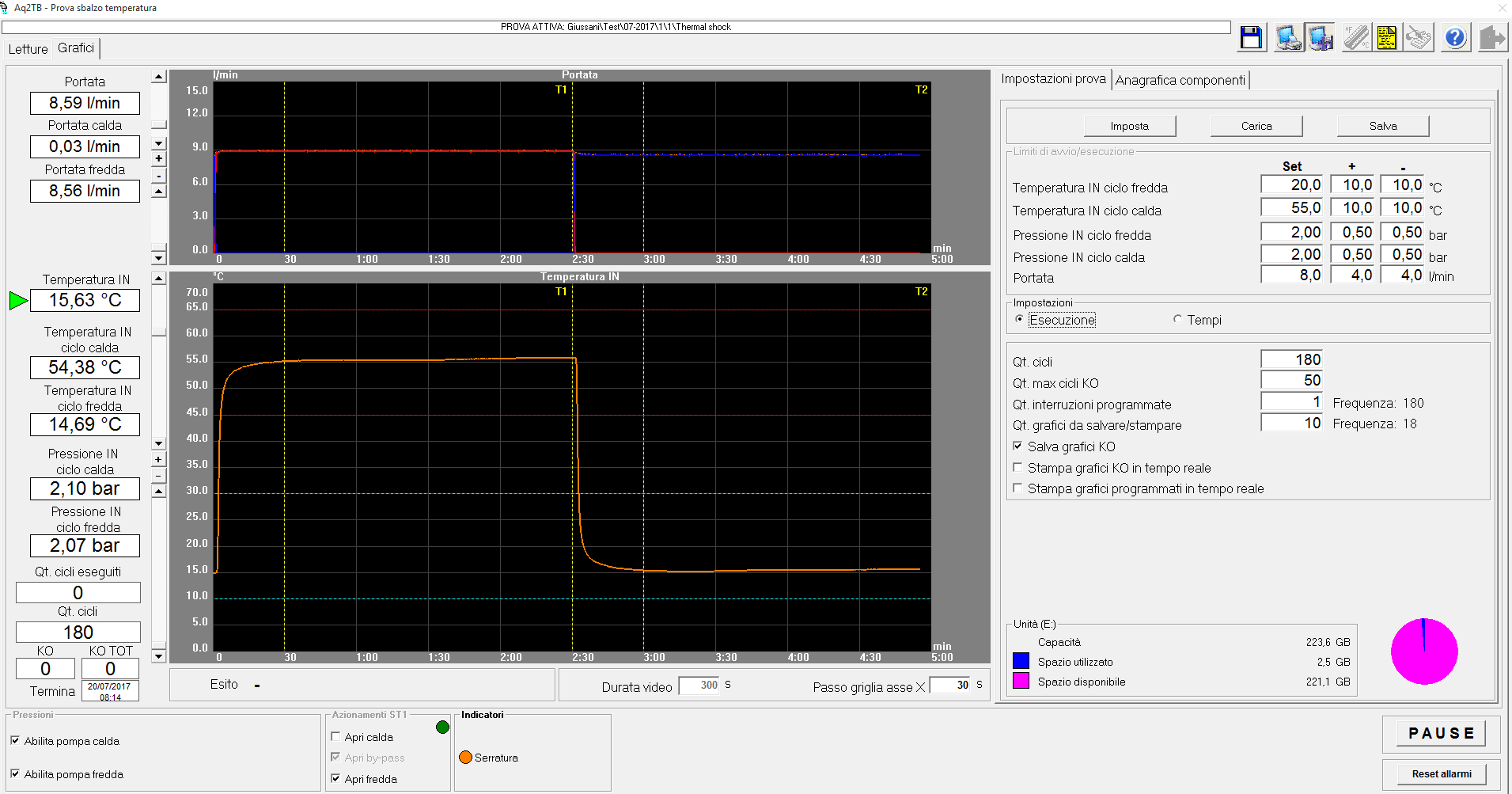

opz-LH&C: Equipment for thermal shock tests

Special equipment and dedicated software for thermal shock tests: this optional device allows to perform tests on showers, flexible hoses and generic devices alternating cold and hot water.

Standard reference: EN 1112 - EN 1113 - NF 079 doc.8

Dedicated software: AQ2TB-LR-ENCSA

Special software on request: AQ2TB-1LM-H&C (EN 1111 chap. 16.8.3 and EN 15092 chap. 7.10)

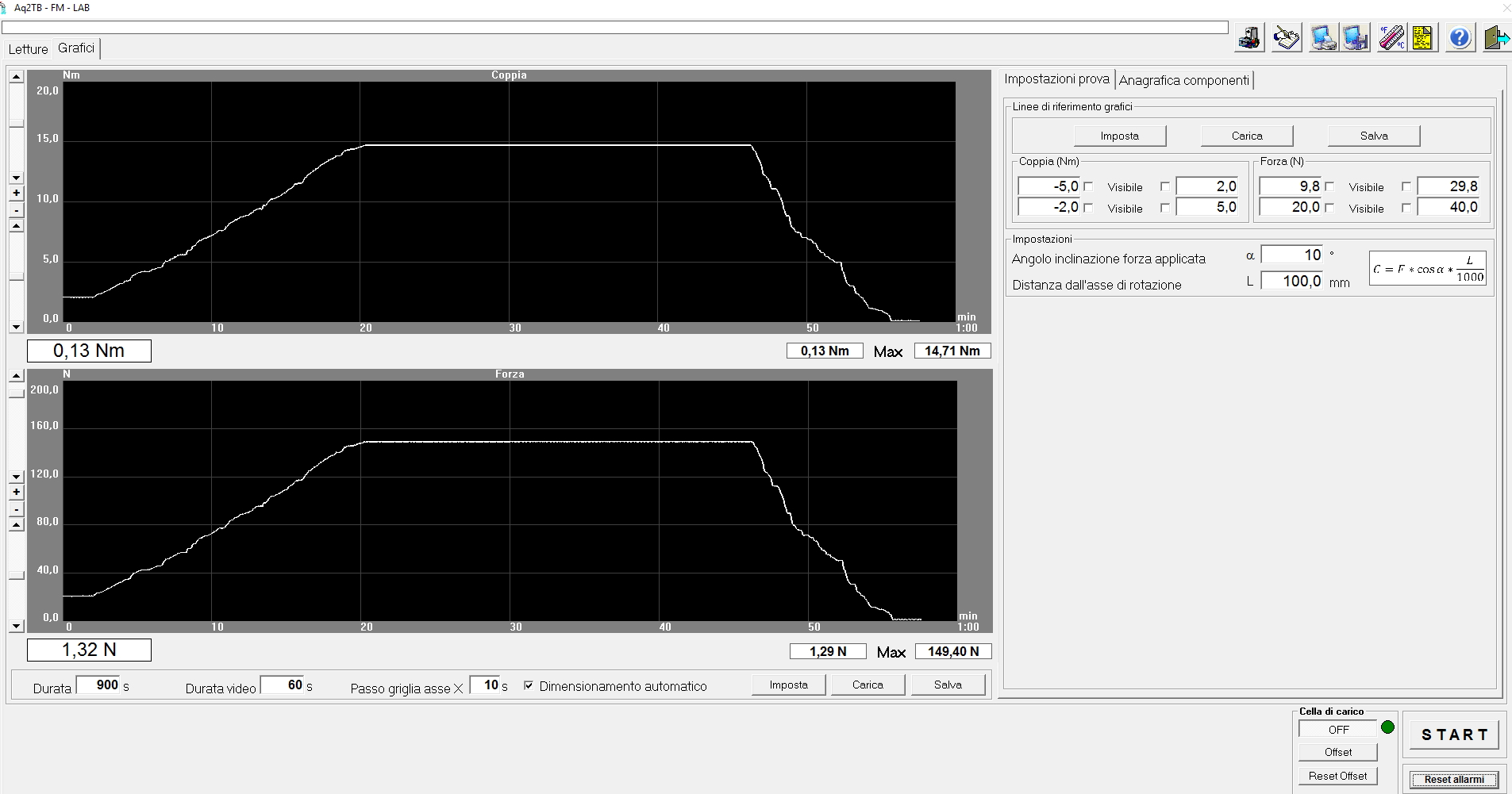

opz-FM: Mechanical device for torsional tests on single lever mixers

Special mechanical equipment to carry out a test to verify the torsional strength of the operating mechanism of mechanical mixing valves according to EN 817 (chapter 11).

Standard reference: EN 817 chap.11

Dedicated software: AQ2TB-COMBI-FM