corpo

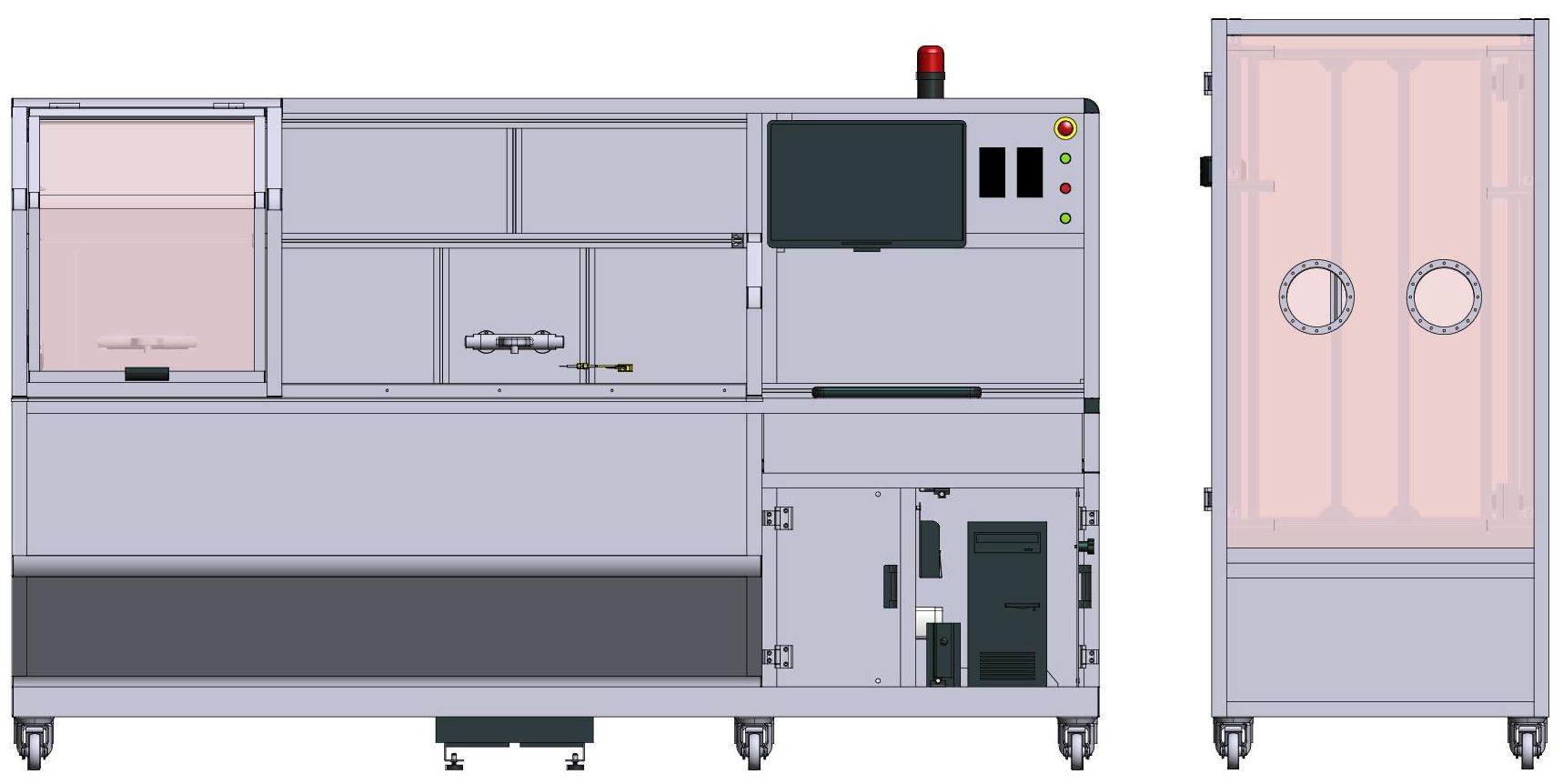

TEST BENCH

LABORATORY TESTS

Code: BPR-SWG5010 + opz-HP + opz-SHOWER

(Flow rate and leaktigtness tests, measurement of the regulating and safety characteristics)

Laboratory test benches to carry out performance tests to measure the hydraulic and regulating characteristics under dynamic conditions such as: stability, response time, sensibility, leakage on sanitary taps. Different models with flow rate up to 105 L/min and adjustable pressure from 0,1 to 10 bar.

- Flow-rate: 47+47 L/min

- Adjustable pressure: 0,1 - 10 bar

- Maximum static pressure: 100 bar

- Pulsing pressure range: 1 - 100 bar

The benches have been designed to verify all sanitary faucets: single lever mixers, swivel spouts, flow control device, automatic diverters, thermostatic mixers, shower mechanisms. By operating in compliance with the most important international standards: NF, EN, CSA, ASME, KIWA, etc... it is possible to perform all the tests manually and some test automatically with a dedicated software by changing all setting parameters. The benches can be implemented with additional options and equipments with dedicated software in order to perform many other relevant tests.

Pdf files

AVAILABLE MODELS

BPR-SWG506: 47+47 L/min - 6 bar

- Flow-rate: 47+47 L/min

- Adjustable dynamic pressure: 0,1-6 bar

- Maximum static pressure: 7 bar

BPR-SWG5010: 47+47 L/min - 10 bar

- Flow-rate: 47+47 L/min

- Adjustable dynamic pressure: 0,1-10 bar

- Maximum static pressure: 11 bar

BPR-SWG1006: 105+105 L/min - 6 bar

- Flow-rate: 105+105 L/min

- Adjustable dynamic pressure: 0,1-6 bar

- Maximum static pressure: 7 bar

BPR-SWG10010: 105+105 L/min - 10 bar

- Flow-rate: 105+105 L/min

- Adjustable dynamic pressure: 0,1-10 bar

- Maximum static pressure: 11 bar

OPTIONAL SOFTWARE AND DEVICES

Software for laboratory tests

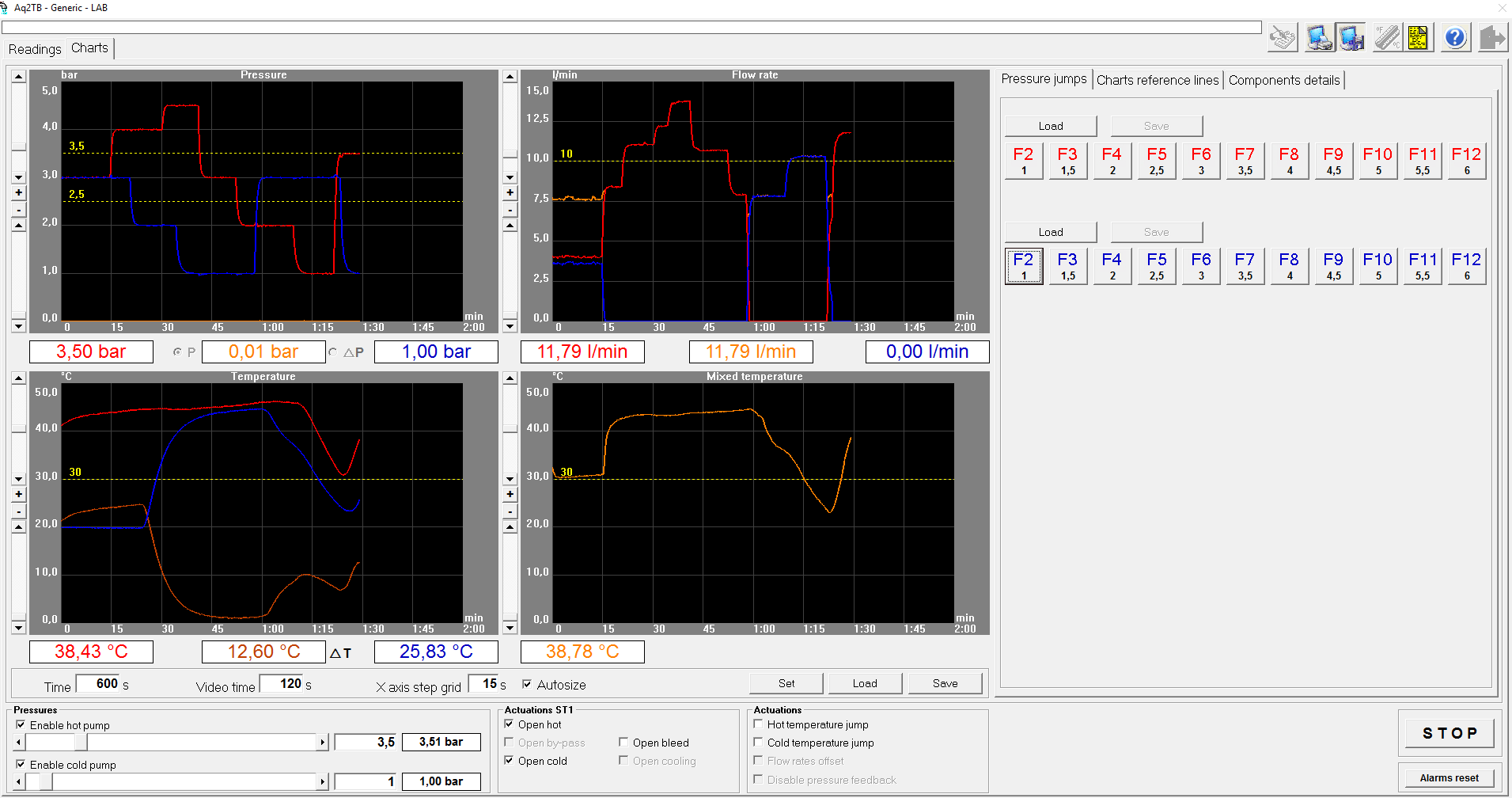

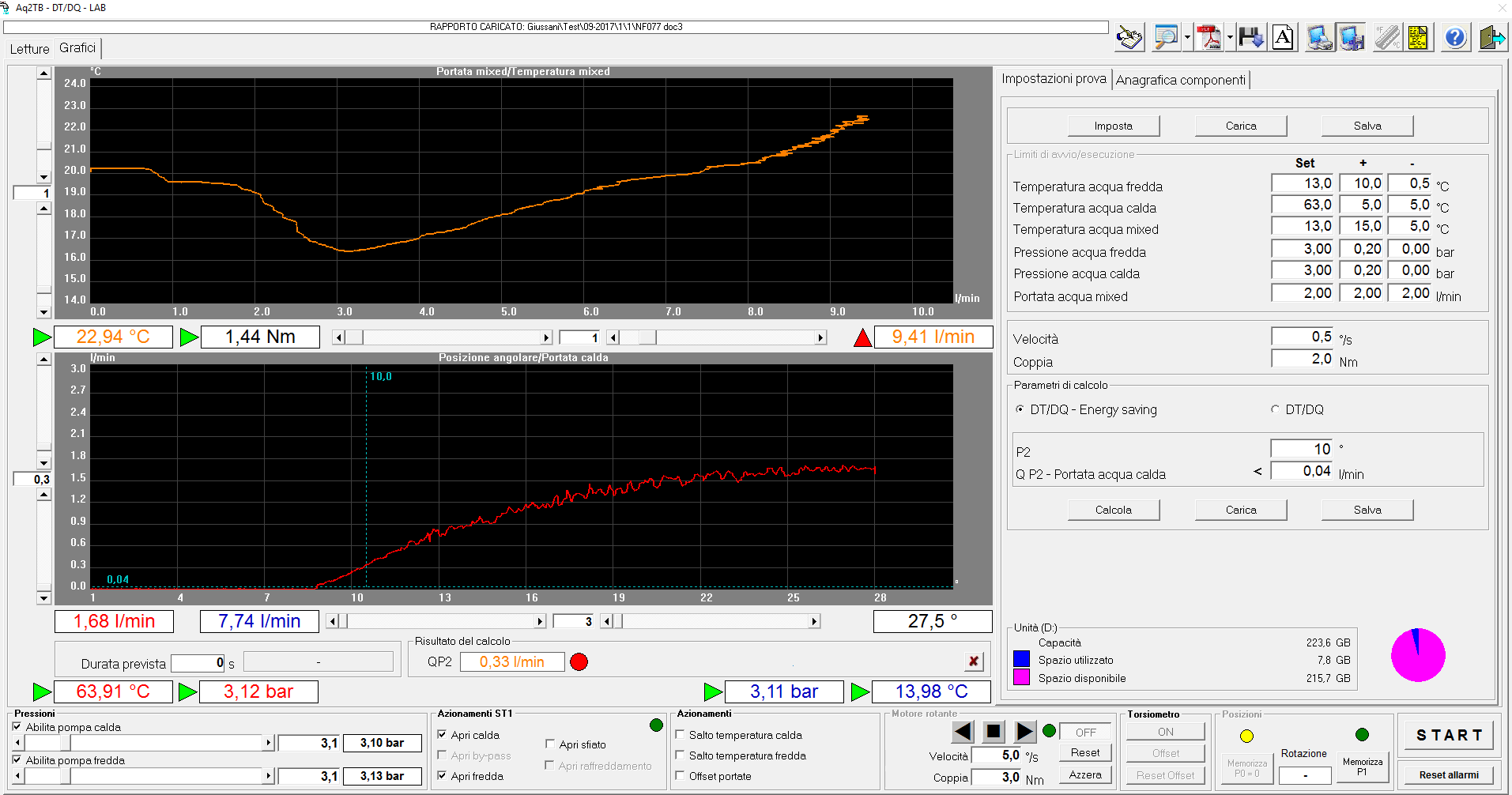

AQ2TB-COMBILAB+: basic software for the measure in real time of flow-rate, pressure and temperature to verify the reaction and the performance of components under test and to perform in addition pressure and temperature jumps tests, flow-rate variation tests and temperature control variation tests.

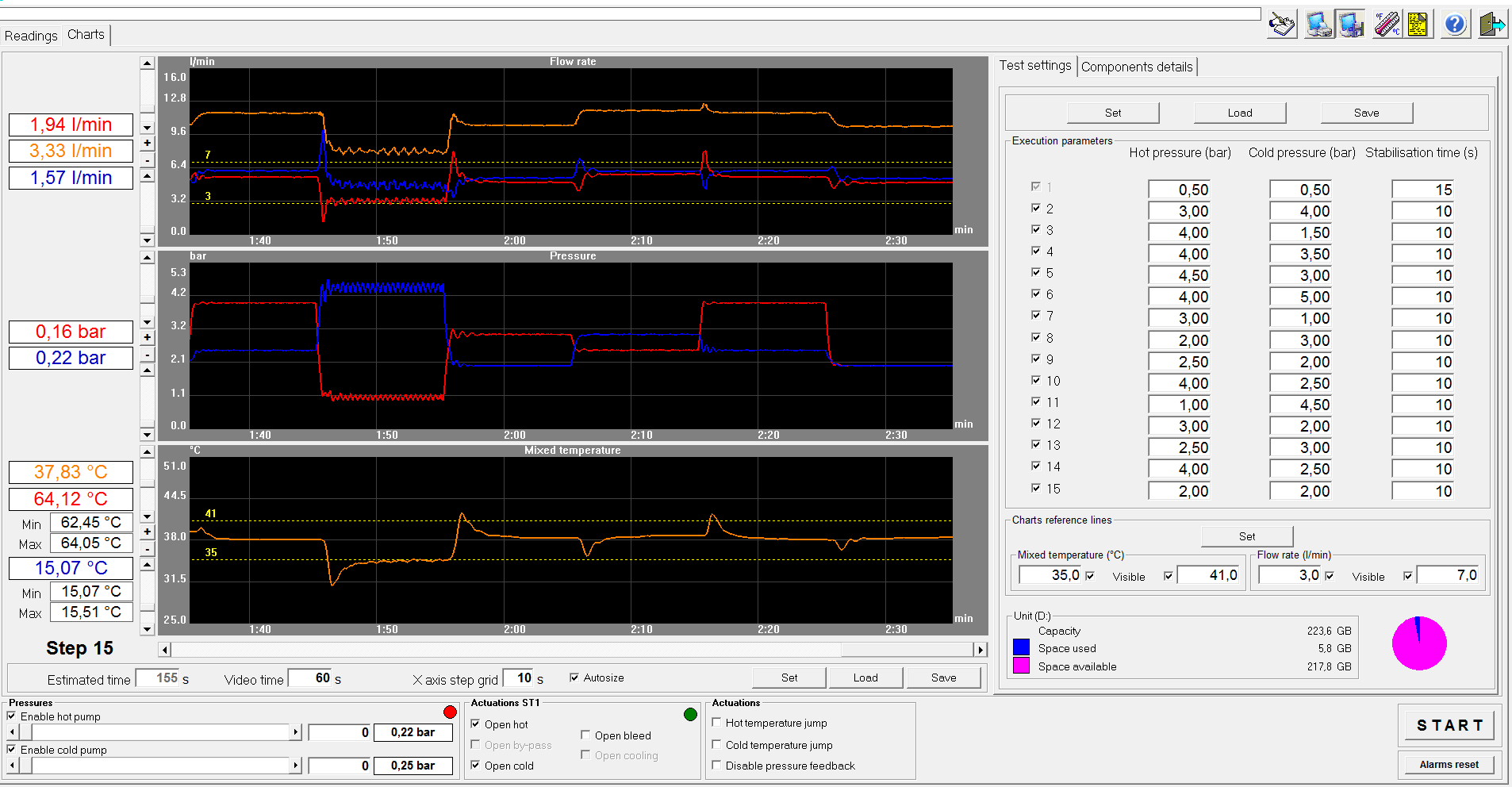

AQ2TB-FLOW-STEP: flow-rate tests with automatic pressure jumps sequence for cold and/or hot water supply, specific for thermostatic mixers. Final report with hot, cold and mixed water flow-rate, pressure and mixed water temperature.

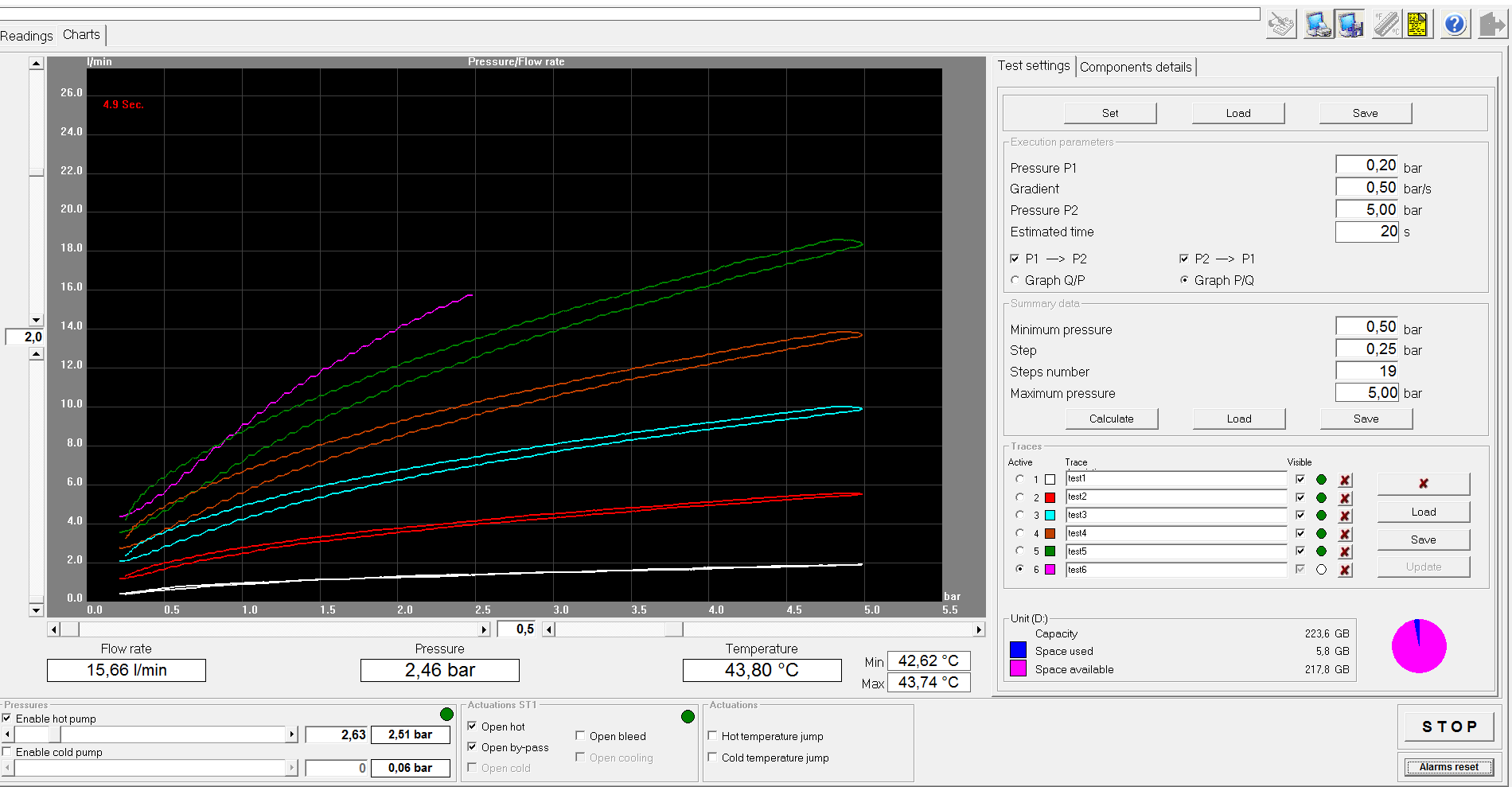

AQ2TB-FLOW-LIN: flow-rate tests with linear increase and/or decrease of pressure and multi-trace flow-rate/pressure or pressure/flow-rate charts.

AQ2TB-M-LAB-NF: software for performing water supply failure tests on thermostatic mixers, adapt for detecting hot water loss in case of cold/hot-water failure, in accordance with NF Standard (NF 077 doc.4 rev.19).

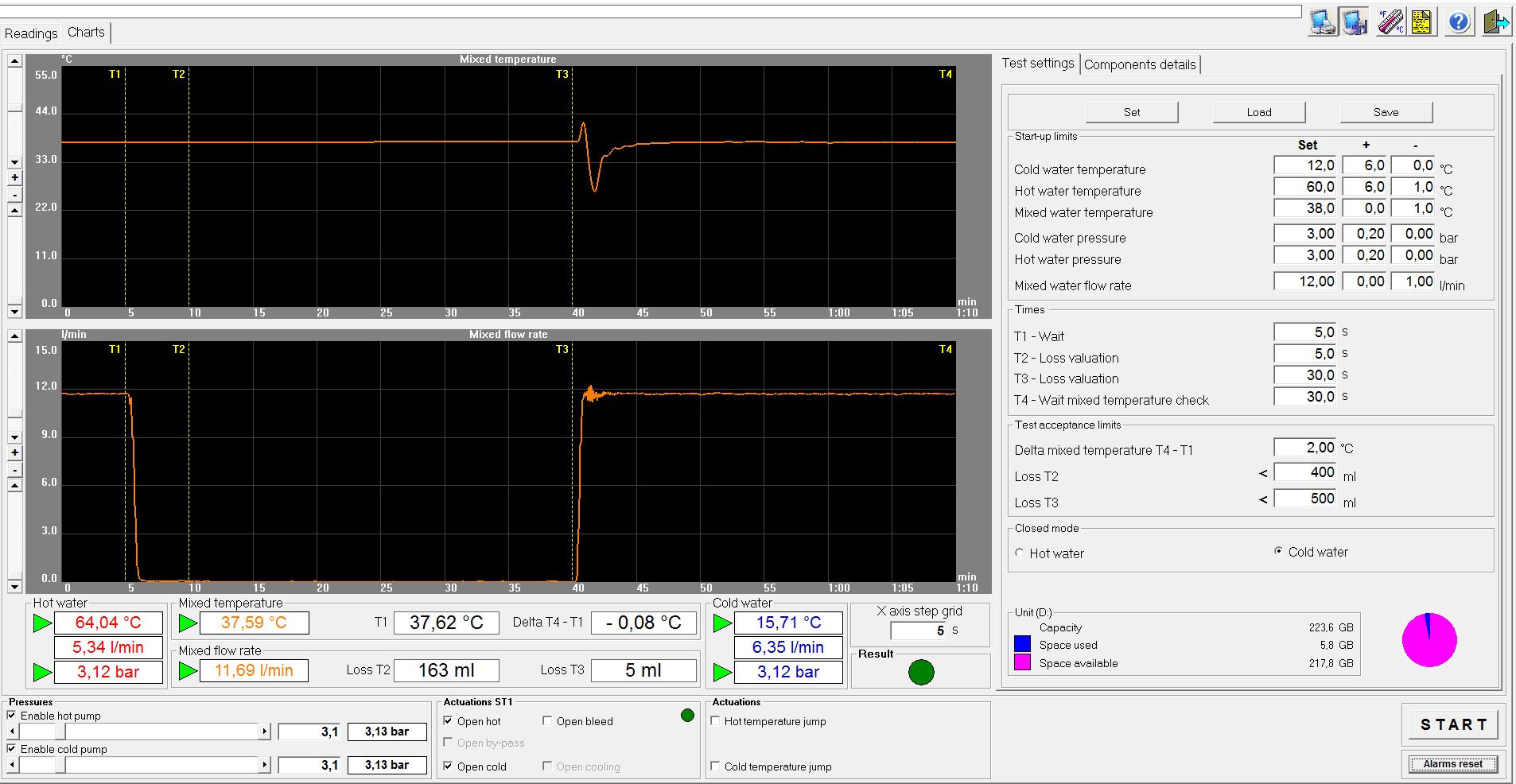

AQ2TB-M-LAB-EN: software for performing water supply failure tests on thermostatic mixers, adapt for detecting hot water loss in case of cold/hot-water failure, in accordance with EN Standard (EN 1111 - 2017).

AQ2TB-M-LAB-D08: software for performing water supply failure tests on thermostatic mixers, adapt for detecting hot water loss in case of cold/hot-water failure, in accordance with D08 Standard (2017).

AQ2TB-M-LAB-CSA: software for performing water supply failure tests on thermostatic mixers, adapt for detecting hot water loss in case of cold/hot-water failure, in accordance with CSA Standard (ASSE/ASME/CSA 1016-2017).

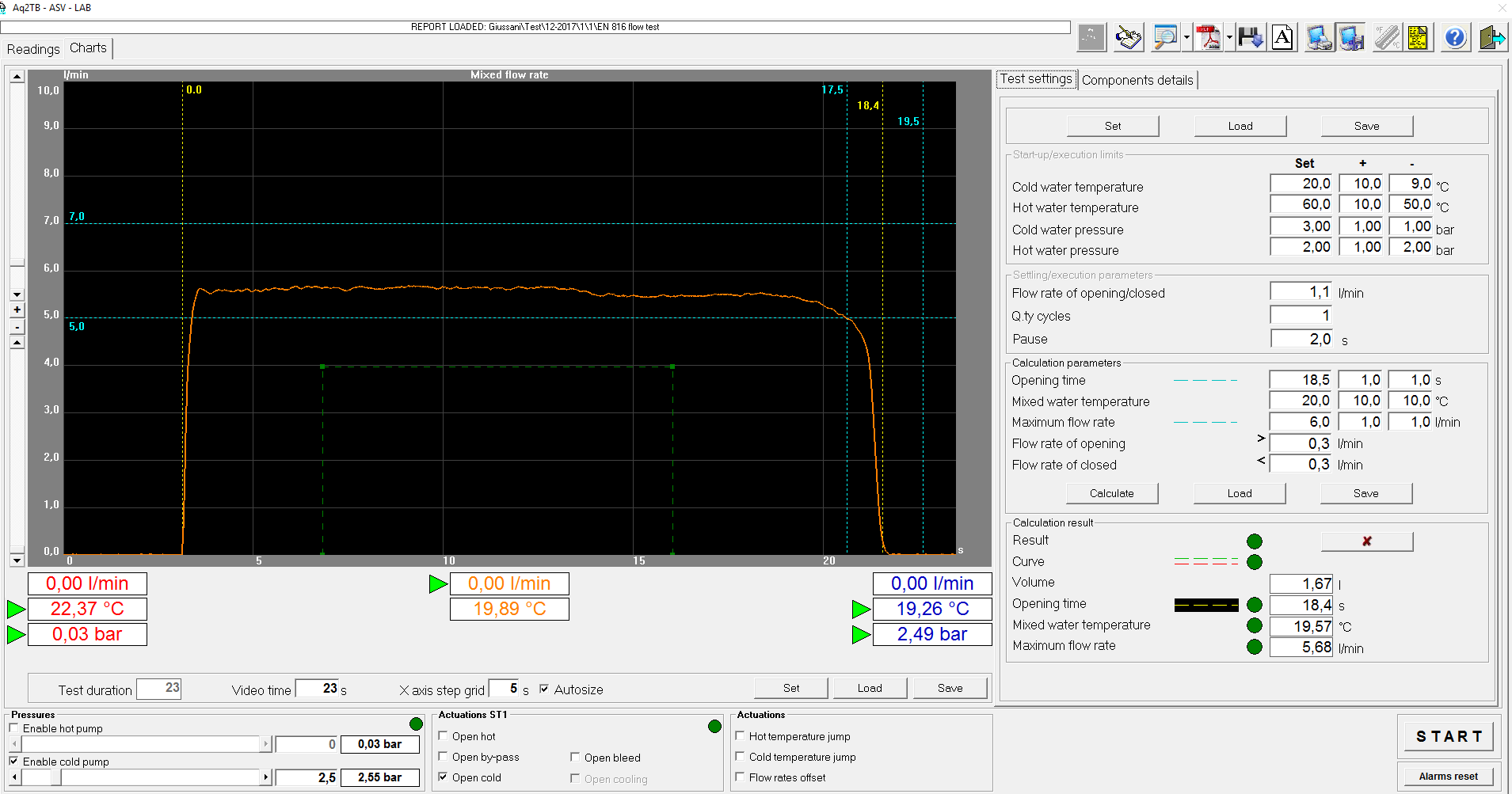

AQ2TB-ASV: software for the automatic execution of flow-rate tests on automatic shut-off valves according to EN 816 Standard. With this software is possible to measure the maximum flow-rate, the opening time, the outlet temperature, the total volume of water and evaluate the shape of flow-rate graph. Anytime is possible to reload a test report, change the calculation parameters and obtain different results.

opz-D08: Test rig according to D08 standard

Hydraulic test rig according D08 Standard.

Includes four thermostatic mixers in order to perfrom two temperature jumps on both water supply lines.

Includes external test rig placed downstream the mixer under test.

opz-DELTAP: Test rig for differential pressure measurements

External adjustable test rig placed downstream the thermostatic mixer under test, includes temperature and pressure boxes and flow-rate valve regulator. Designed according EN 1111 Standard.

The equipment is required to measure the performance of thermostatic mixers to simulate the pressure and temperature loss due to the components installed after the taps under test.

opz-DIGM: Digital manometer 0÷1000 mbar

Low-pressure digital manometer, the device allows a very precise measurement of dynamic pressure delivered in the range up to 1 bar.

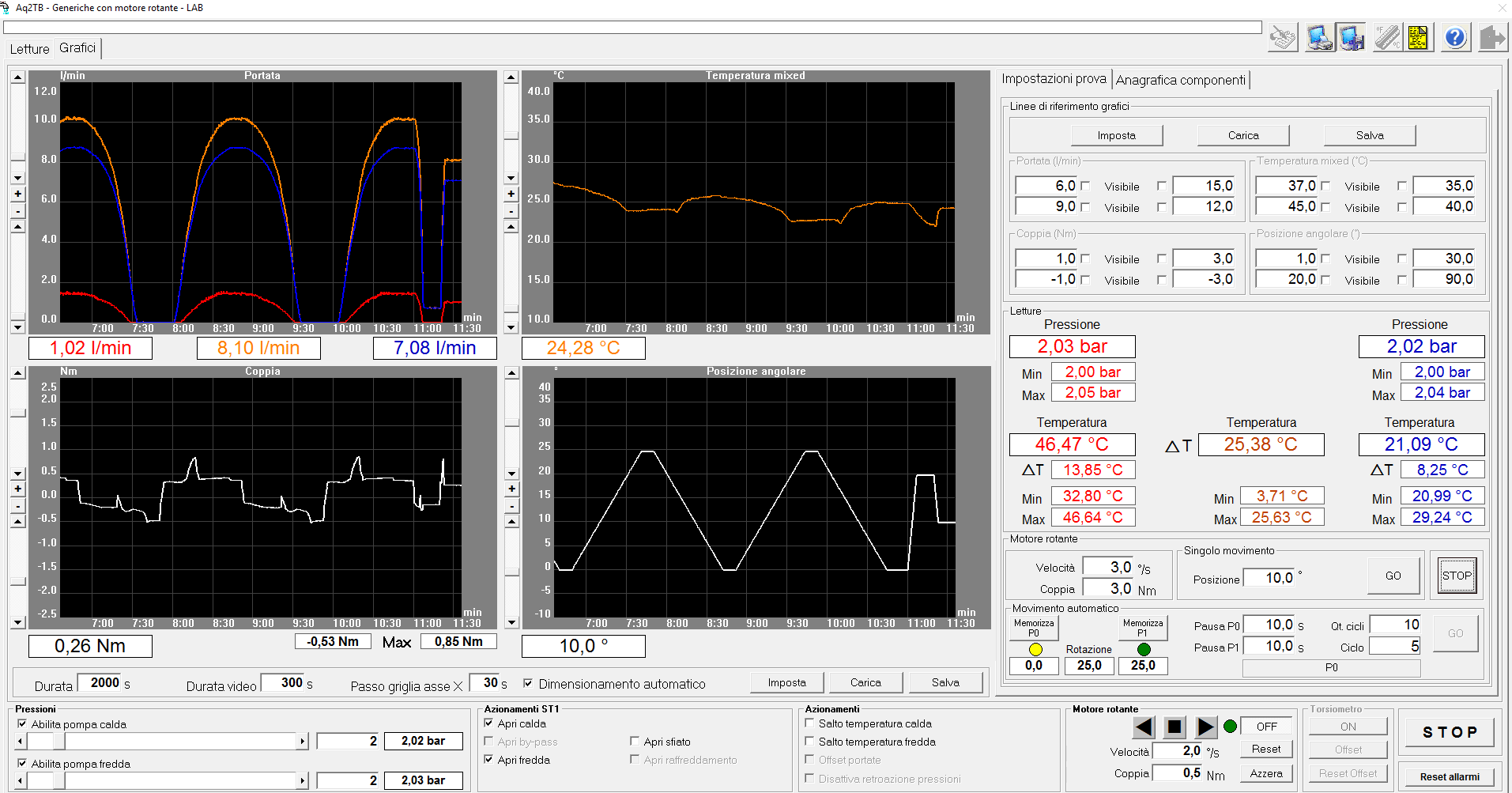

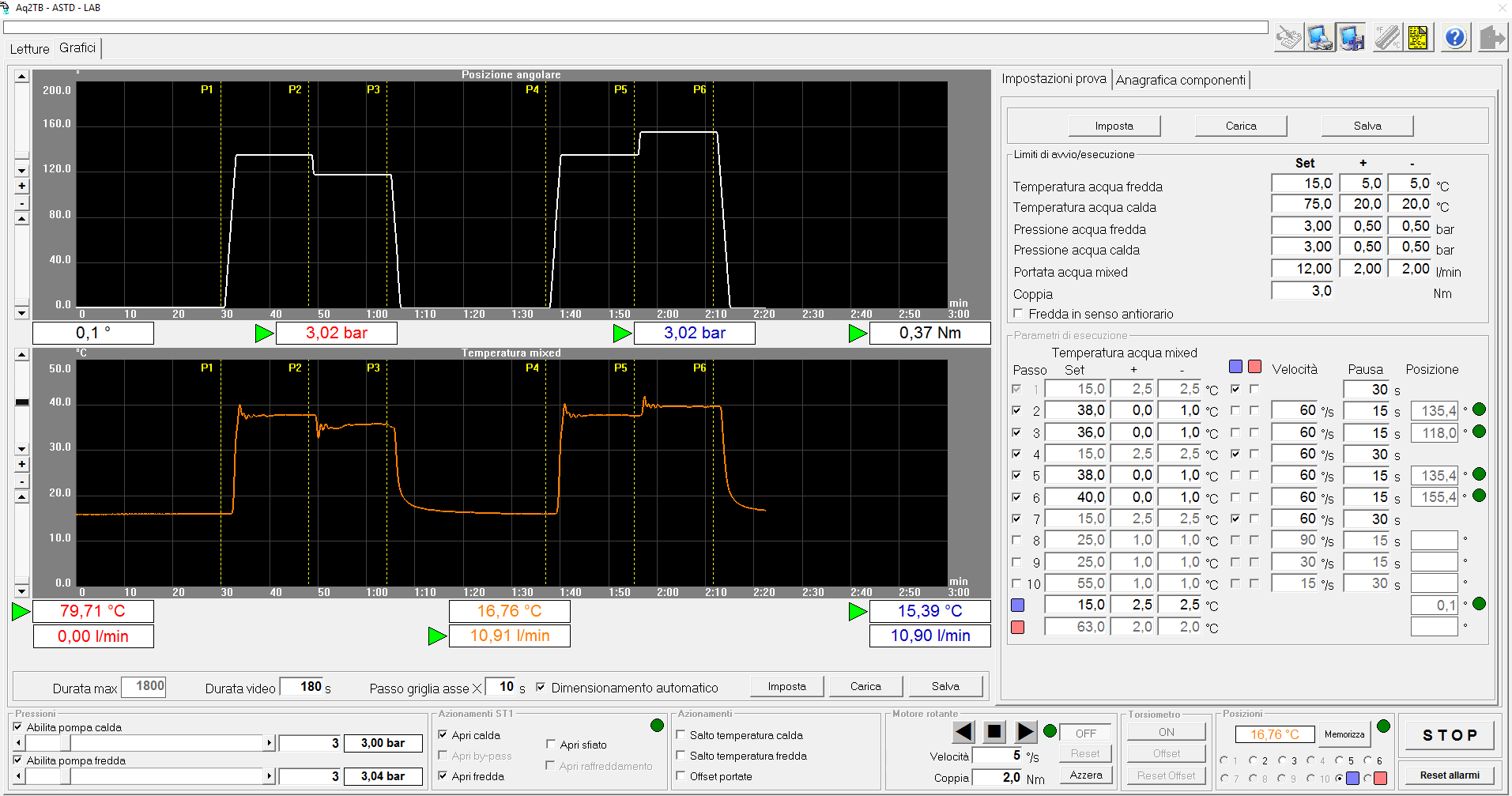

opz-ROTMOT: Rotary motor

Brushless rotary motor with feedback control of the supplied torque. For each test, the dedicated software allows to control in real-time the angular position, the speed and set the maximum resistant torque acceptable.

Features:

- Adjustable rotating speed: 0,5 - 300 °/s

- Adjustable torque 1 - 10 Nm

- Adjustable angular position: 0 - 3600 °

Available software AQ2TB-COMBI-RM designed to perform, with the use of the rotary motor, manual movements or simply programmable automatic movements sequences. It allows the measure of torque and angular position and the evaluation of the gotten results.

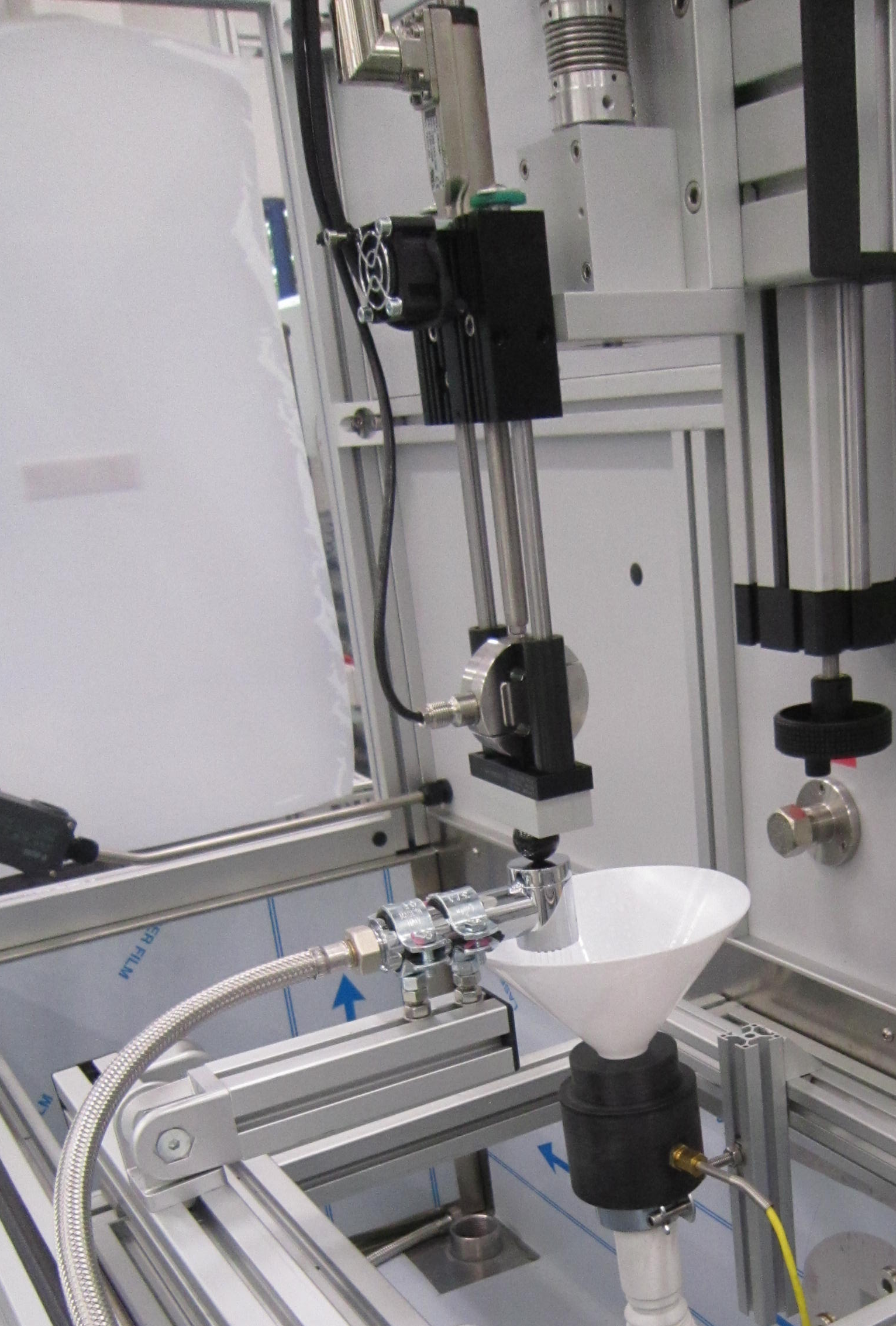

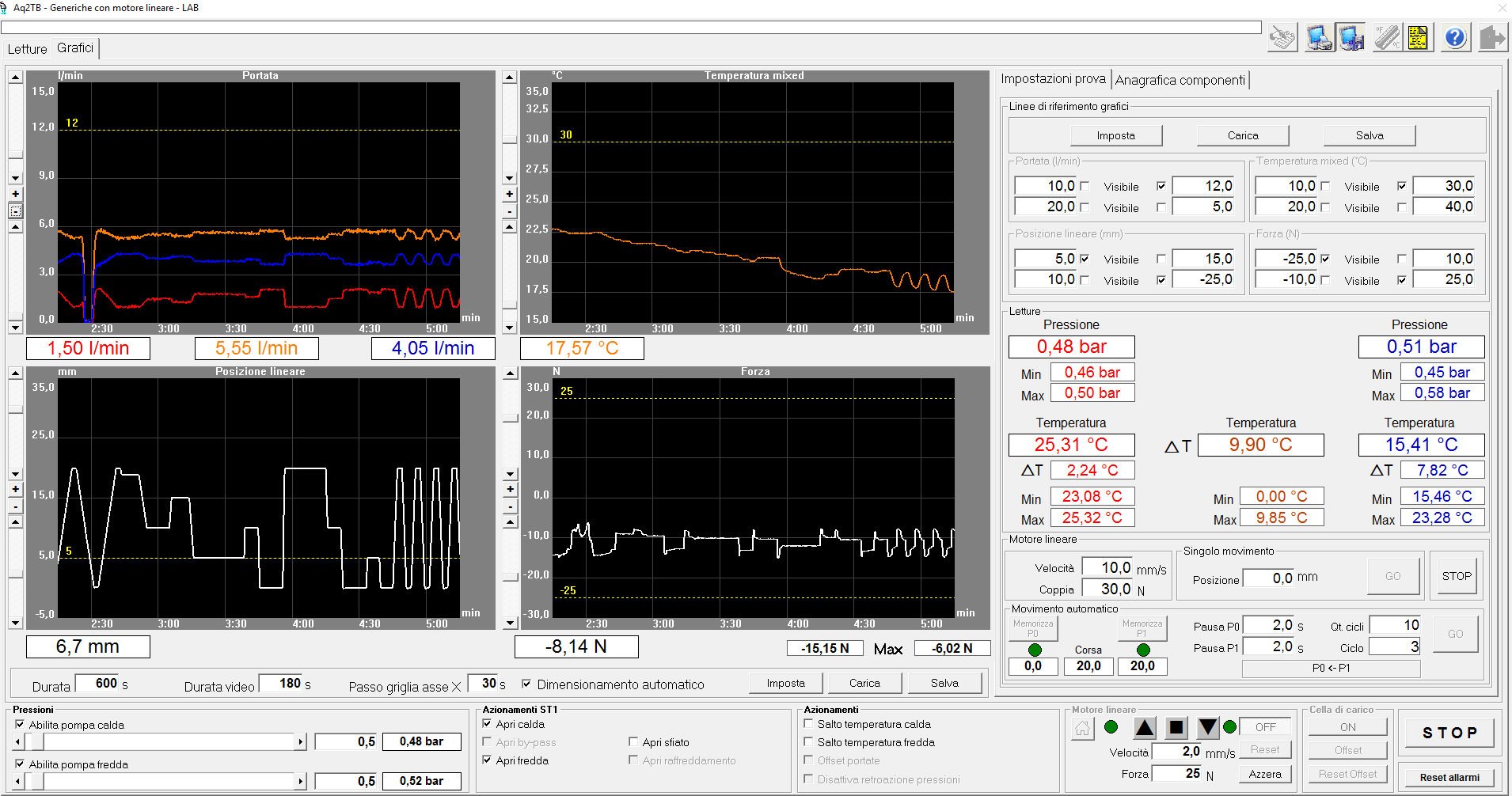

opz-LINMOT: Linear motor

Electromagnetic linear motor with feedback control of the supplied force. For each test, the dedicated software allows to control in real-time the linear position, the speed and set the maximuum resistant force acceptable.

Features:

- Adjustable linear speed: 1 - 300 mm/s

- Adjustable force 1 - 44 N

- Adjustable linear position: 0 - 100 mm

Available software AQ2TB-COMBI-LM designed to perform, with the use of the linear motor, manual movements or simply programmable automatic movements sequences. It allows the measure of force and linear position and the evaluation of the gotten results.

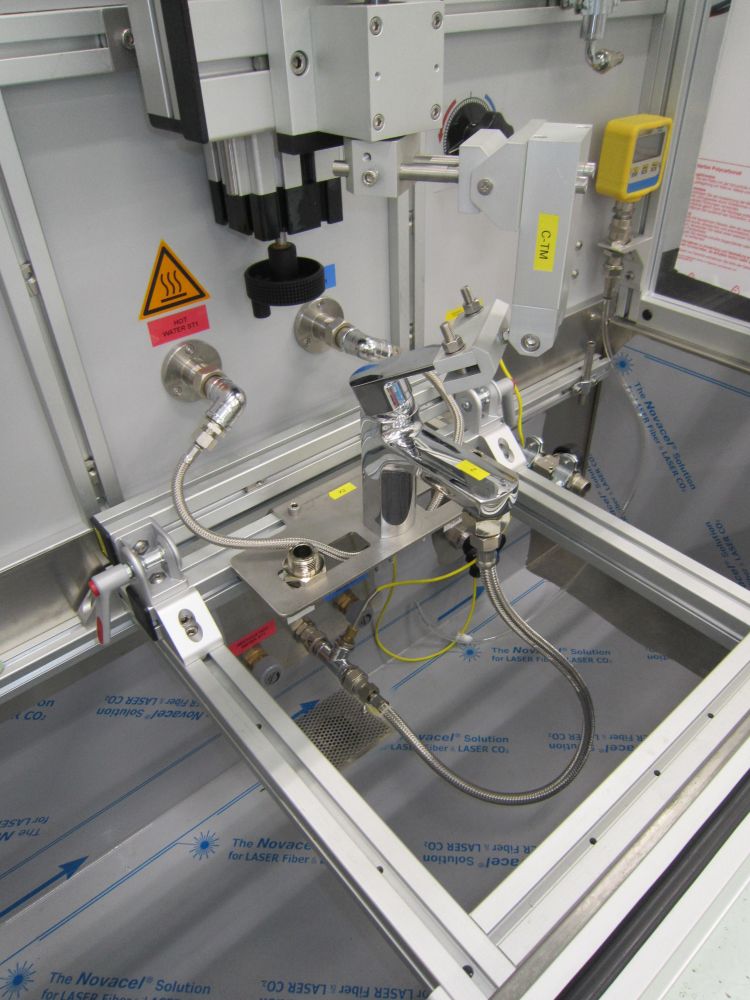

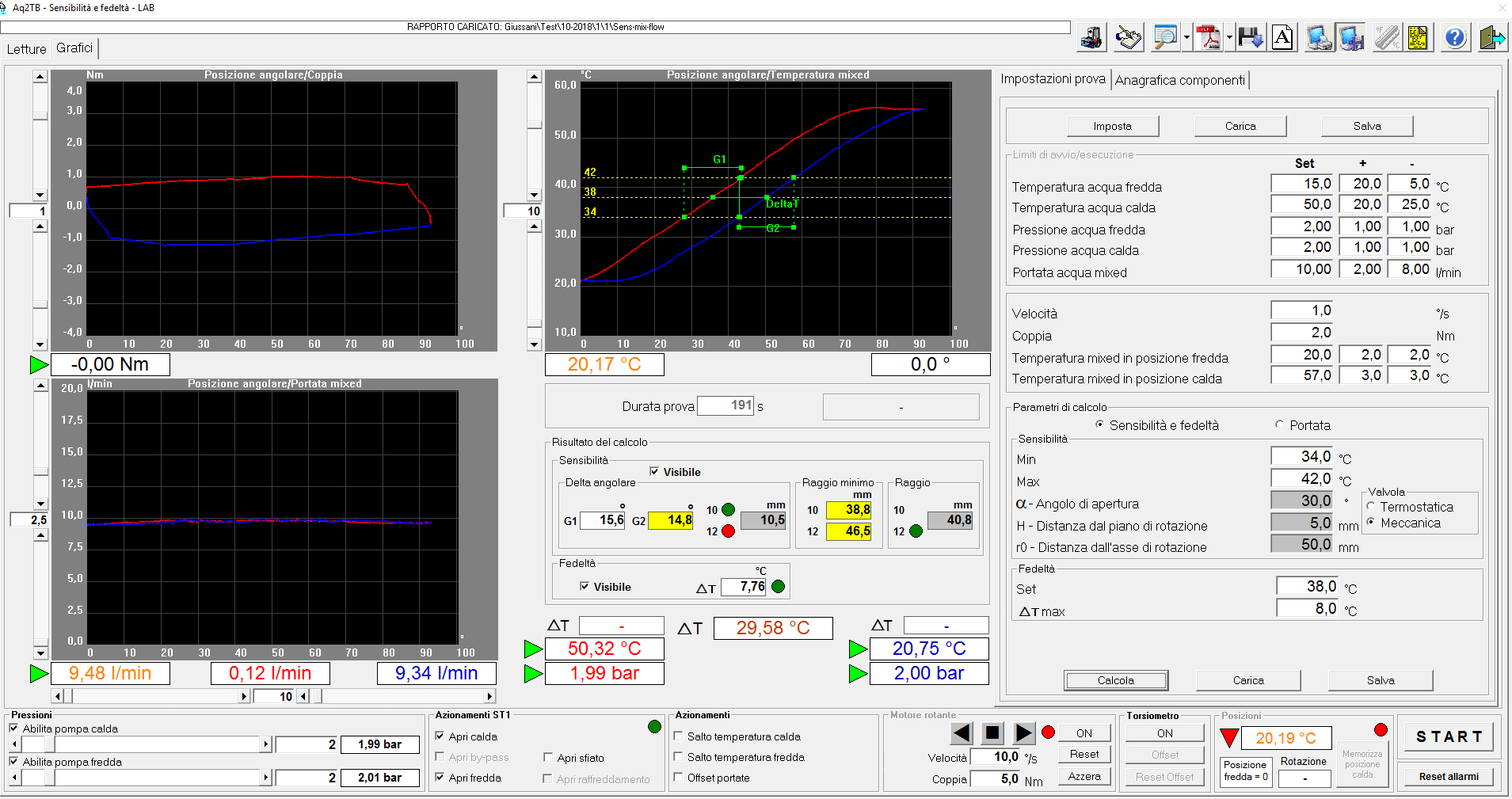

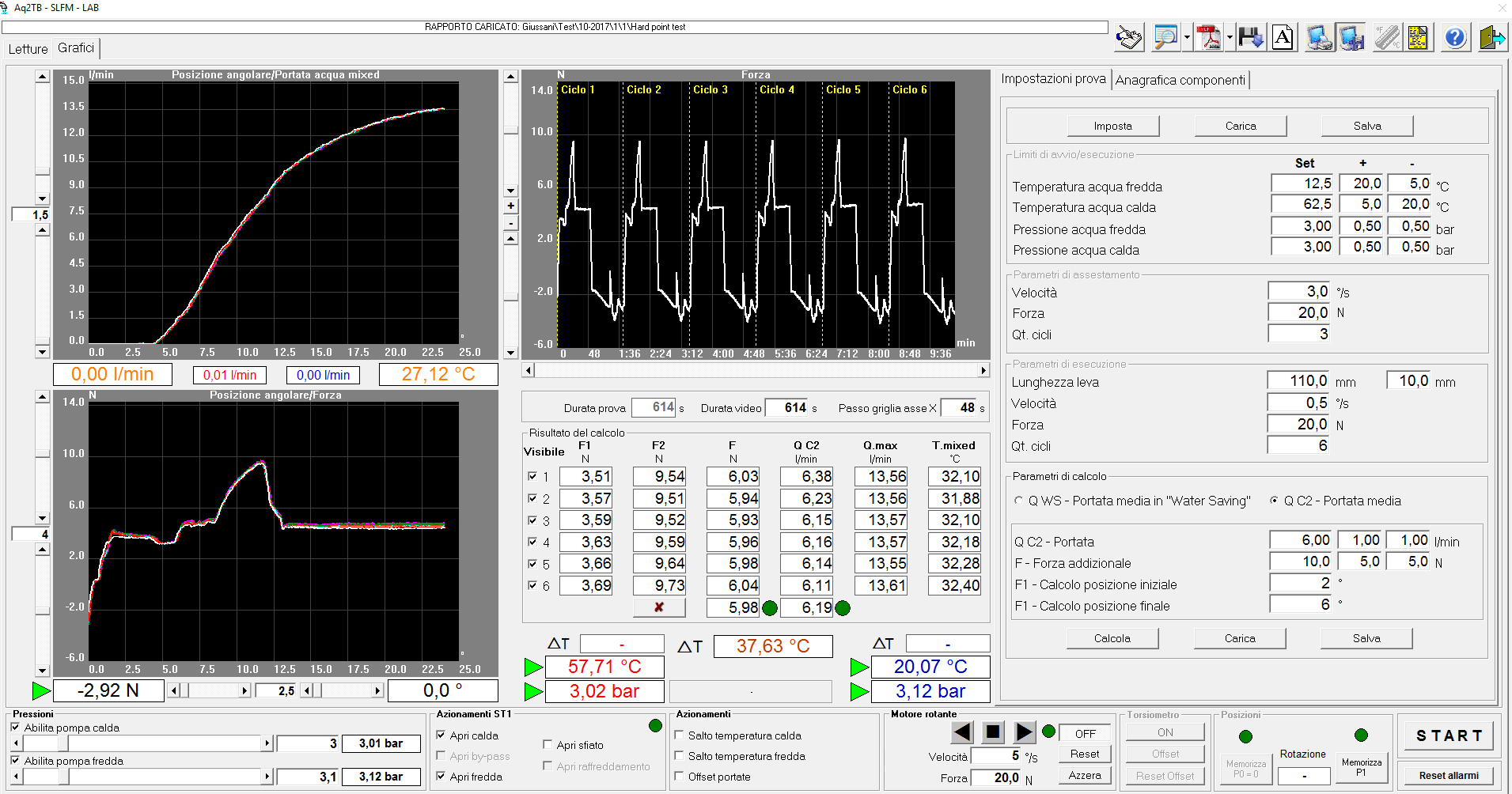

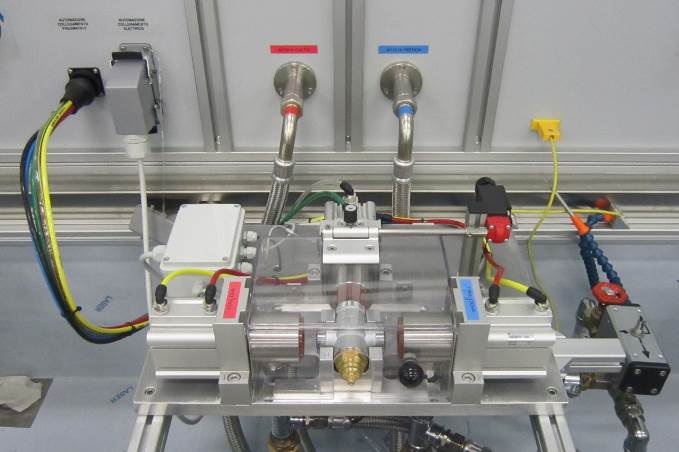

opz-C-TM: Fidelity and sensitivity tests

Mechanical device for fidelity and sensitivity tests on thermostatic and mechanical mixers according Standards EN 1111 e EN 817.

The procedure consists to move the temperature control handle from cold to hot position and return at controlled speed with stable water supply conditions, measuring the mixed water temperature as a function of the angular position.

Includes the dedicated software AQ2TB-F+S-DRIVE to perform automatically the test and evaluate the final results according the parameters set by the user. Includes the measure of the flow-rate according Standard EN 817.

AQ2TB-ASTD: Temperature control operation (thermostatic mixers)

Dedicated software for the verification of the mixed water temperature changes upon fast temperature control operations according Standard EN 1111 chap. 13.5.1.

opz-SL-FM: Rating ECAU according Standard NF 077 for mechanical mixers - C2 classification

Device for measuring the force necessary to move the handle of a mechanical mixer and measure the strength of hard point F2-F1 according Standard NF 077 doc.3 rev.19.

Includes dedicated software AQ2TB-SLFM:

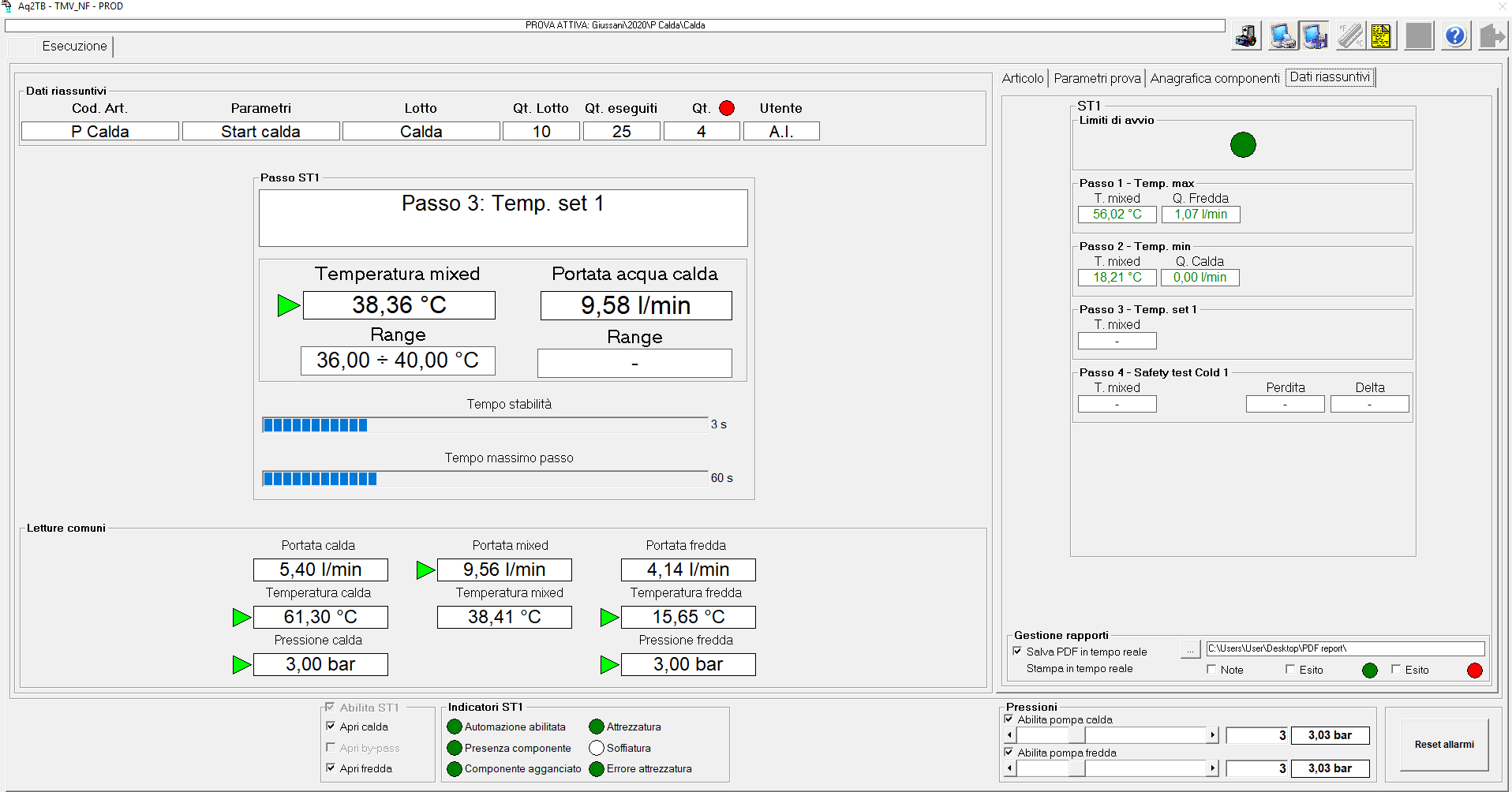

opz-TP: Clamping device for automatic production tests on thermostatic mixers

This equipment includes the clamping device and special supports, box control, micro switches, safety door and air blowing plants.

Includes dedicated software with safety test according NF Standard: AQ2TB-TMV-PROD-NF.

Available on request special clamping devices and test sequences.

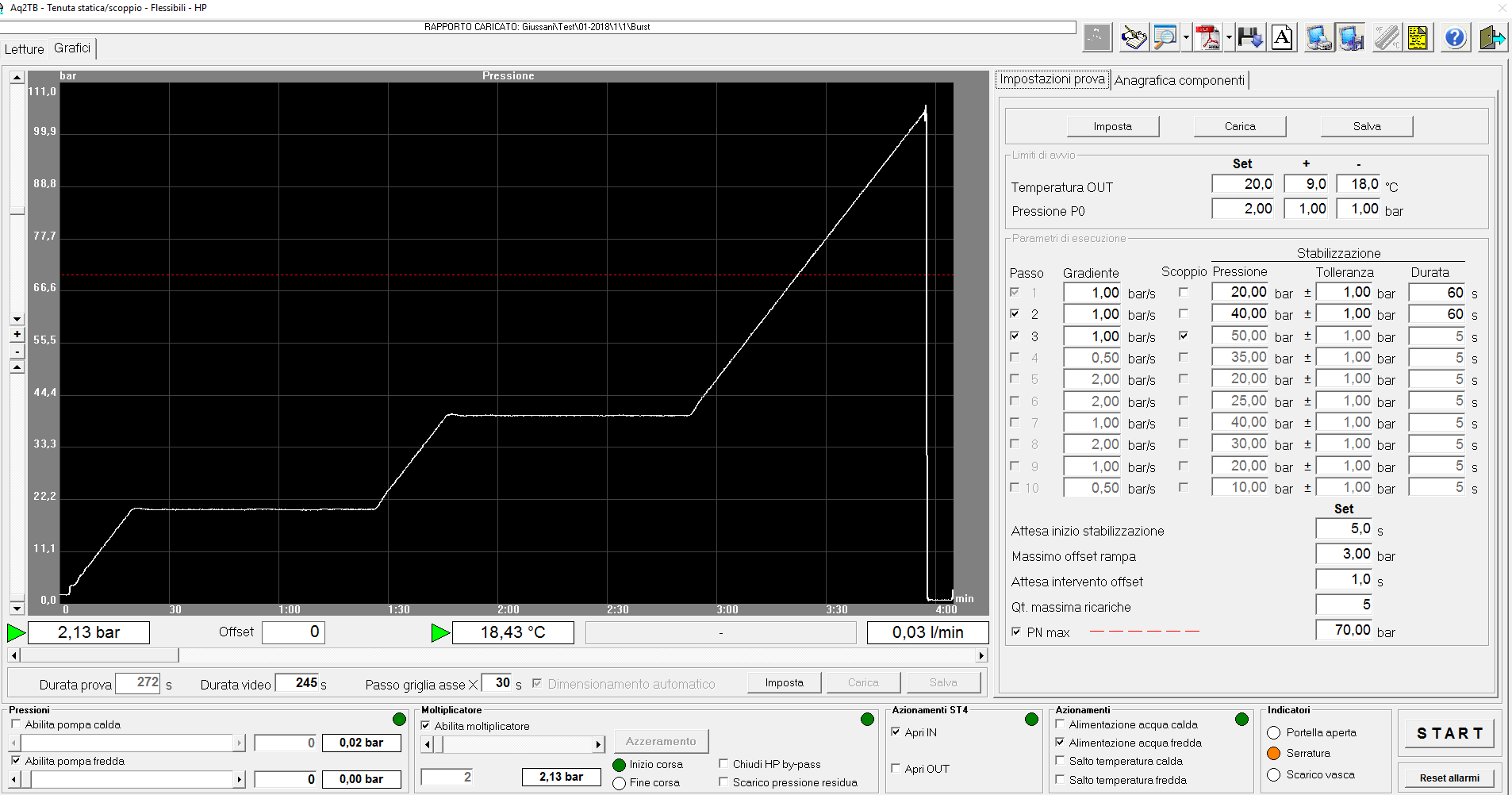

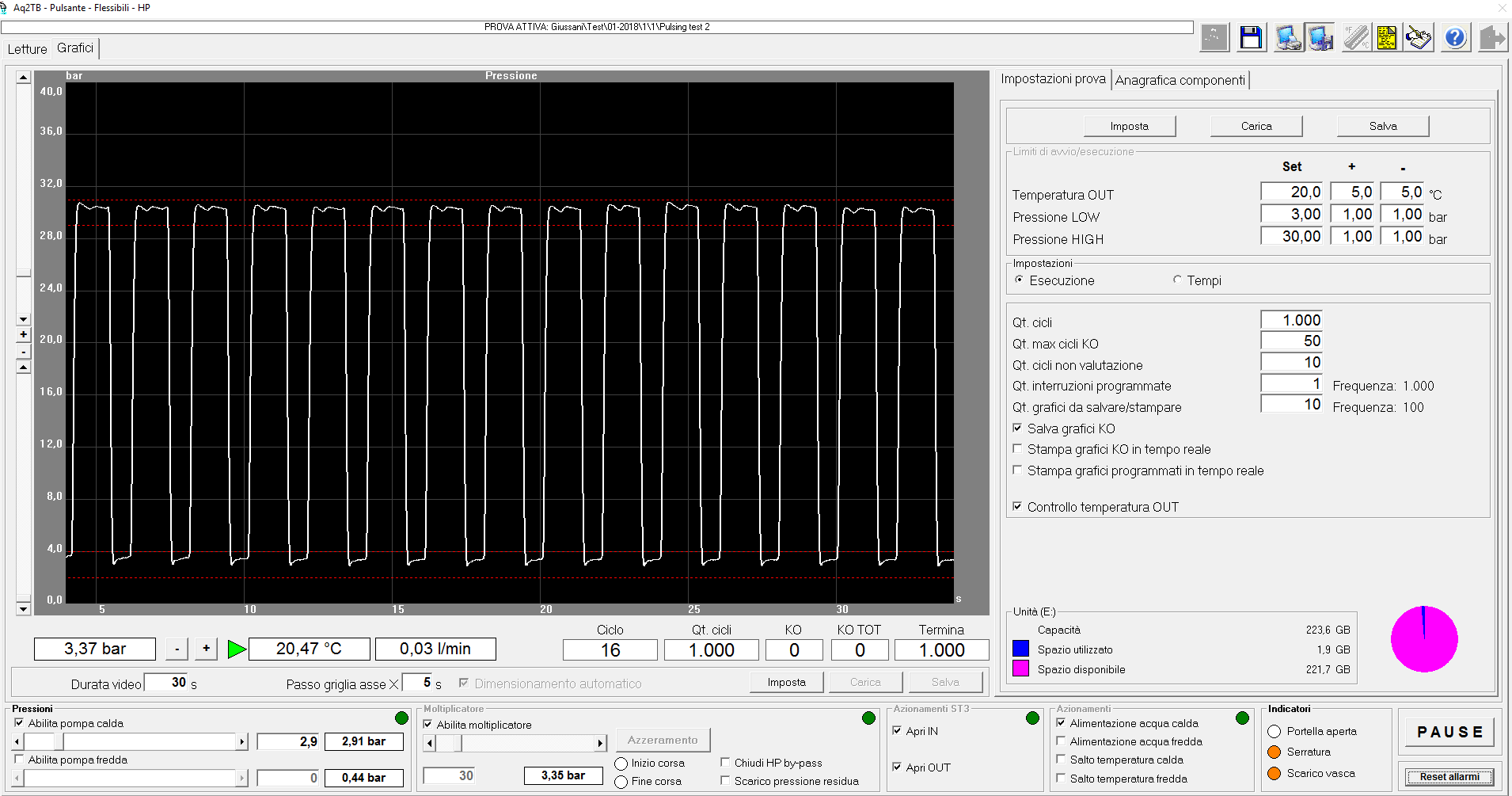

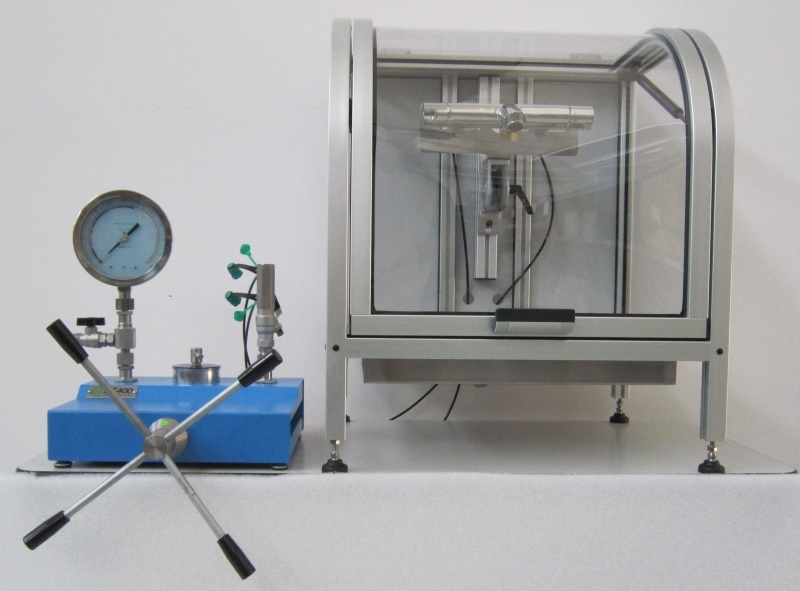

opz-HP: Station for static/burst tests and water hammer resistance tests up to 100 bar

Additional test station for chack of mechanical performances under static pressure tests and pulsing pressure tests.

Includes pressure intensifier (1:17), safety door with micro switch and dedicated software.

AQ2TB-STATICAUT: software for static/burst tests with up to 10 customizable steps (rising/falling ramps, stabilization time and pressure set by the user).

AQ2TB-PULSEAUT: software for pulsing pressure tests in order to check the water hammer resistance up to 100 bar according NF Standard.

opz-HP-FLEX: High pressure test station for static and pulsing pressure tests on flexible hoses

Special high pressure station for static/burst tests and pulsing pressure tests on flexible hoses.

Maximum static pressure: 200 bar - Pulsing pressure: 0-100 bar.

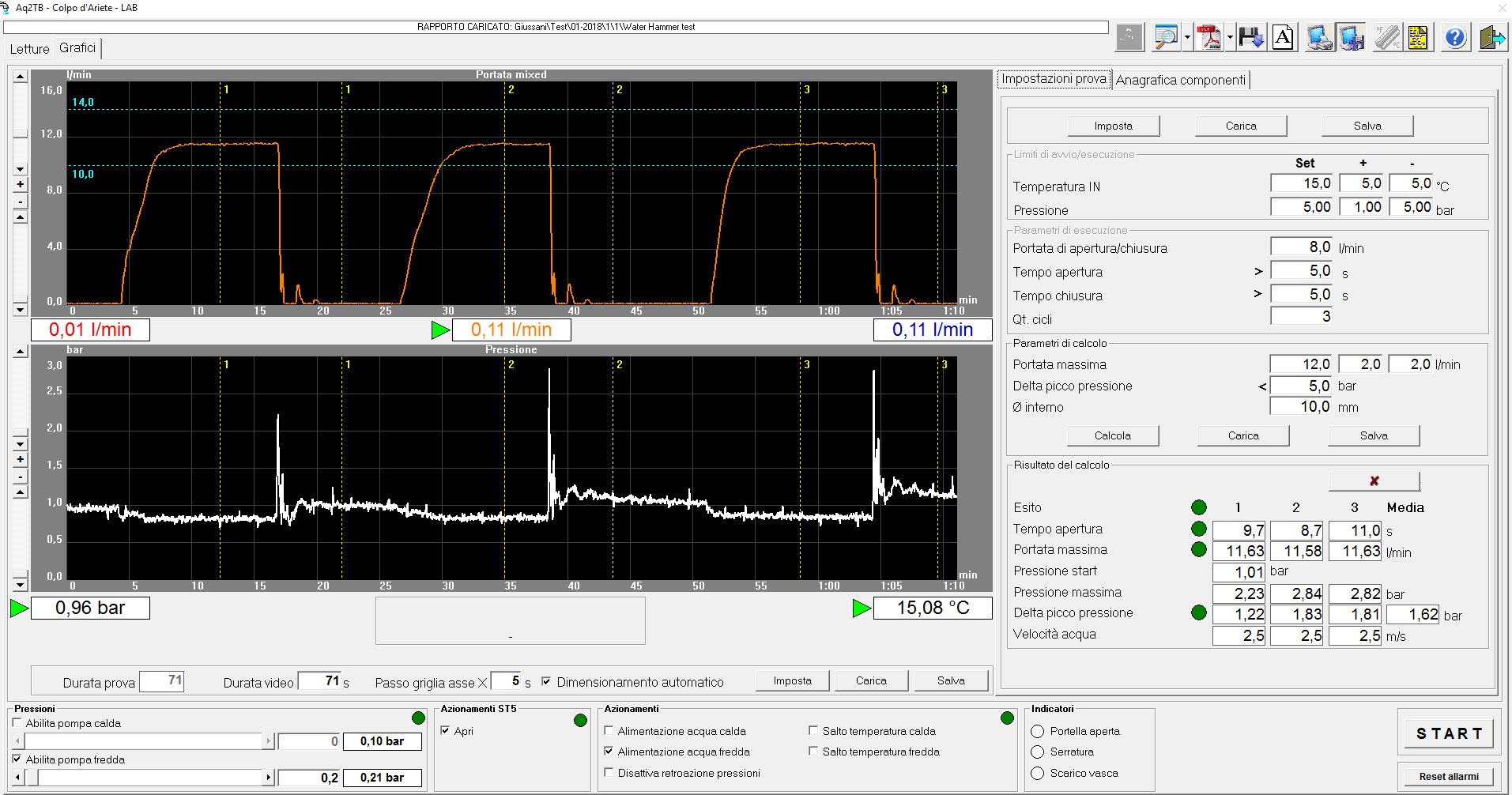

opz-HAMTEST: Measure of water hammer produced by electronic opening/closing of sanitary tapware

Hydraulic test rig and test sequence according Standard EN 15091. Includes 9 m copper tube and high frequency pressure transducer.

Includes dedicated software AQ2TB-HAMTEST for the guided execution of the test. Possibility to perform customized evaluation after the execution of the test.

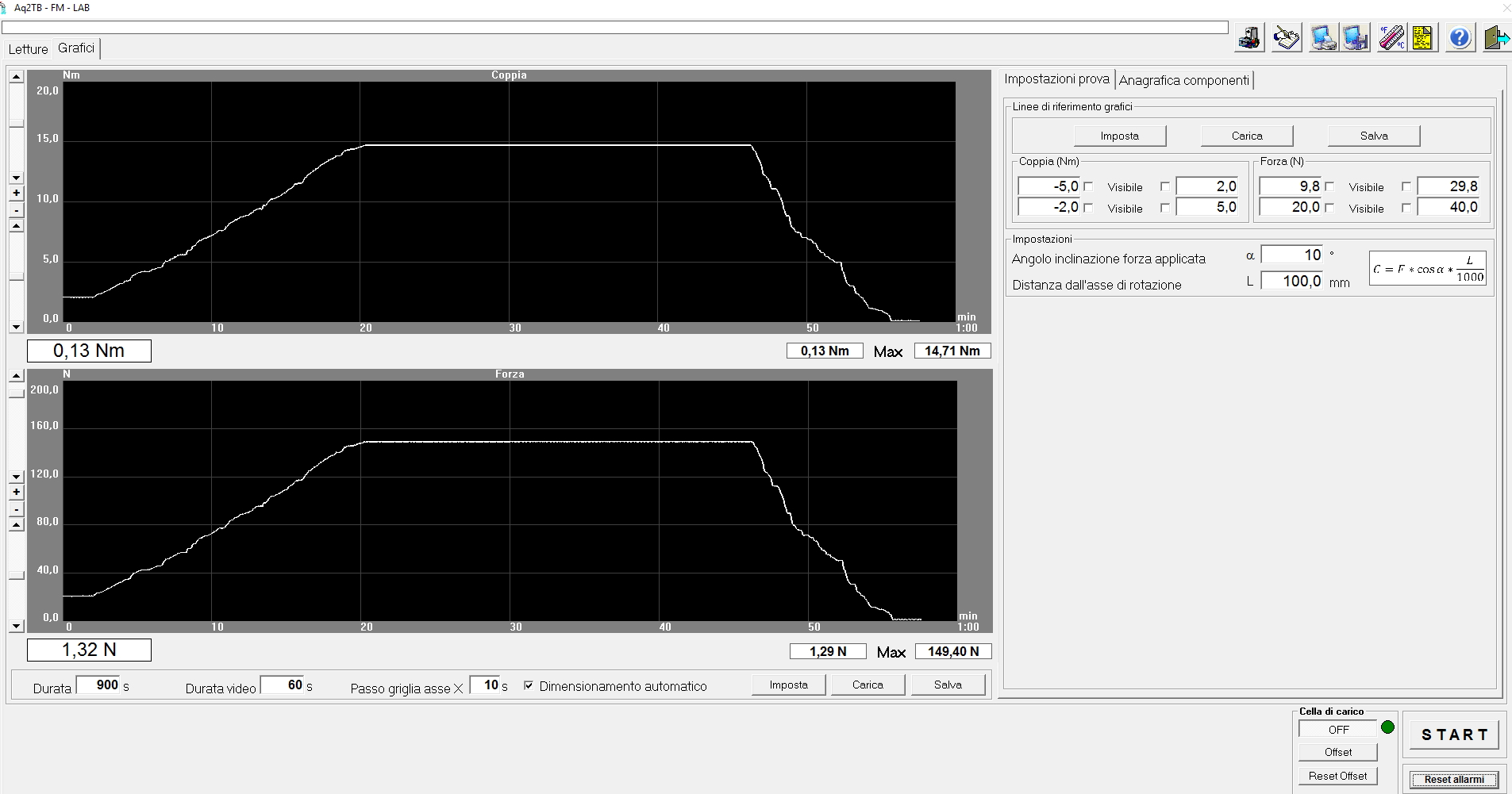

opz-FM: Mechanical device for torsional tests on single lever mixers

Special mechanical equipment to carry out a test to verify the torsional strength of the operating mechanism of mechanical mixing valves according to EN 817 (chapter 11).

Standard reference: EN 817 chap.11

Dedicated software: AQ2TB-COMBI-FM

AQ2TB-DT/DQ: Rating ECAU according Standard NF 077 for mechanical mixers - C1, C3 and Ch3 classification

Automatic software for flow-rate variation tests and C1, C3 and Ch3 classification of mechanical mixers according Standard NF 077 doc.3 rev.19.

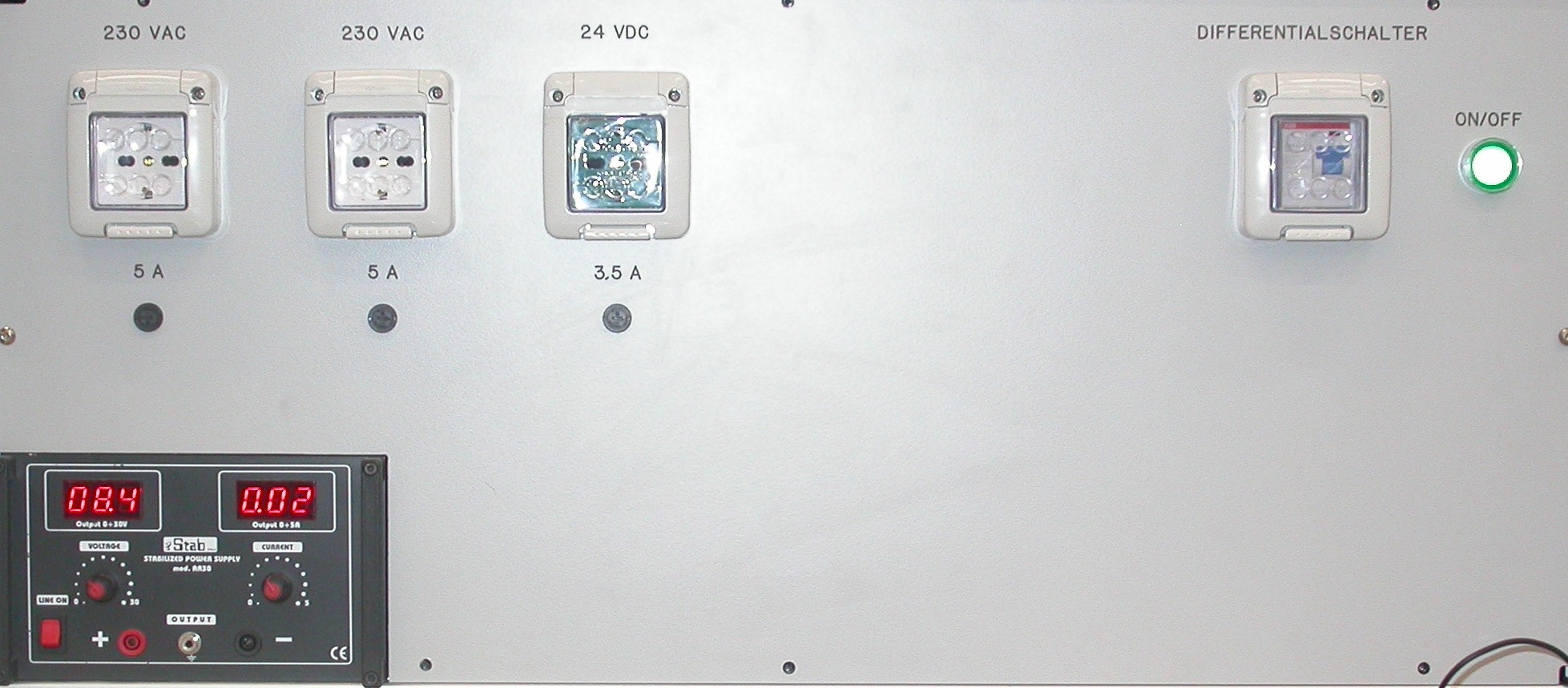

opz-ES01: Electric supply panel for electronic tapware

The panel includes three sockets (230 V AC - 230 V AC - 24 V DC) and one variable power supplier 0-30 V DC - 0-5 A.

The sockets are proteced by an isolation transformer and safety push-button.

opz-Q-FLEX: Device for flow-rate tests on flexible hoses

Adjustable telescopic support device for flow-rate tests on flexible hoses, with length from 500 mm up to 2000 mm.

Accessories

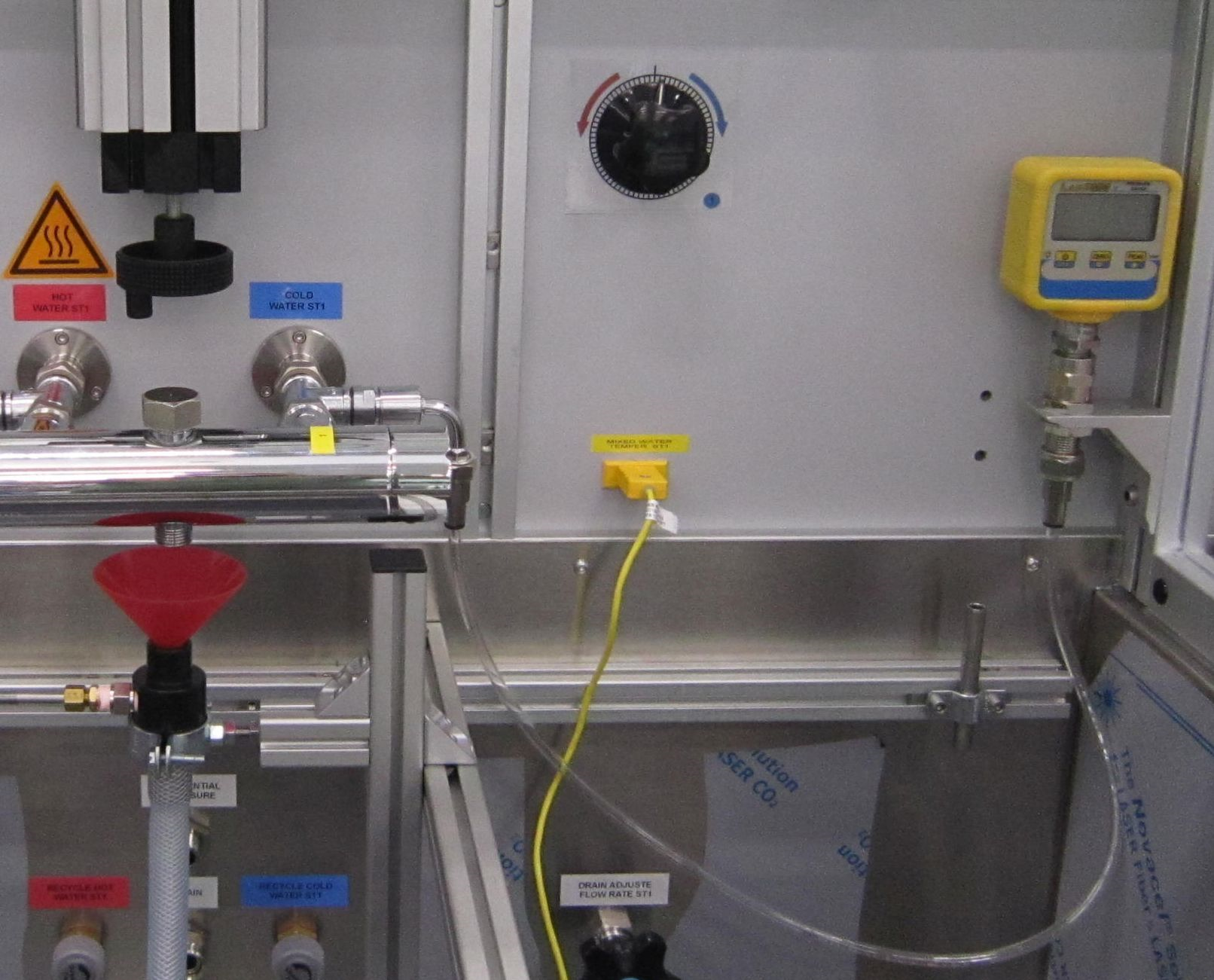

opz-SHOWER: Cabin for testing showers and shower columns

The cabin, connected to the test bench, allows the functioning check of showers and shower columns.

Structural frame made by high-tensile aluminium profiles and side panel glass made, stainless steel internal tank with recovery pump, assembly on rotating wheels provided with parking brakes.

Standard testing area: 820 x 820 x (h) 1500 mm.

Special cabinets available on request.

Note: The cabin can be used for flow-rate tests, but IS NOT possible evaluate automatically the pressure loss due to the water supply flexible hoses between bench and cabin.

BT400-RUB-COVER: Hand pressure generator

Hand pump for the execution of static/burst tests up to 400 bar.

Note: The actual maximum pressure depends on the pressure transducer installed.

Includes the protection cover aluminium+polycarbonate made and stainless steel water recovery tank.

BT400-TO-SWG: dedicated package for the connection of the hand pump to the BPR-SWG test bench. Includes 100 bar pressure transducer, electric arrangement for the connection to the test bench and dedicated software AQ2TB-COMBI-EXT for the data acquisition and the generation of test reports.

ENDURANCE TESTS: Optional equipments for endurance tests

Optional devices for the execution of endurance tests on the laboratory test benches:

OPZ-LM: Endurance tests on mechanical single lever mixers.

OPZ-LBM: Endurance tests on swivel spouts.

OPZ-LR: Endurance tests on taditional and ceramic single taps.

OPZ-LPC: Endurance tests on progressive cartridges.

OPZ-LCD: Endurance tests on diverter cartridges.

OPZ-LD: Endurance tests on linear diverters.

OPZ-LCT: Endurance tests on thermostatic mixers (thermal element).

OPZ-LMWS: Endurance tests on shower mechanisms and multi-ways selectors.

OPZ-LH&C: Thermal shock tests.